Product Description

Specification

|

1.

|

Configurations

|

Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching

Device,Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. |

|

2.

|

Control System

|

PLC Inverter Encoder Touch Screen

|

|

3.

|

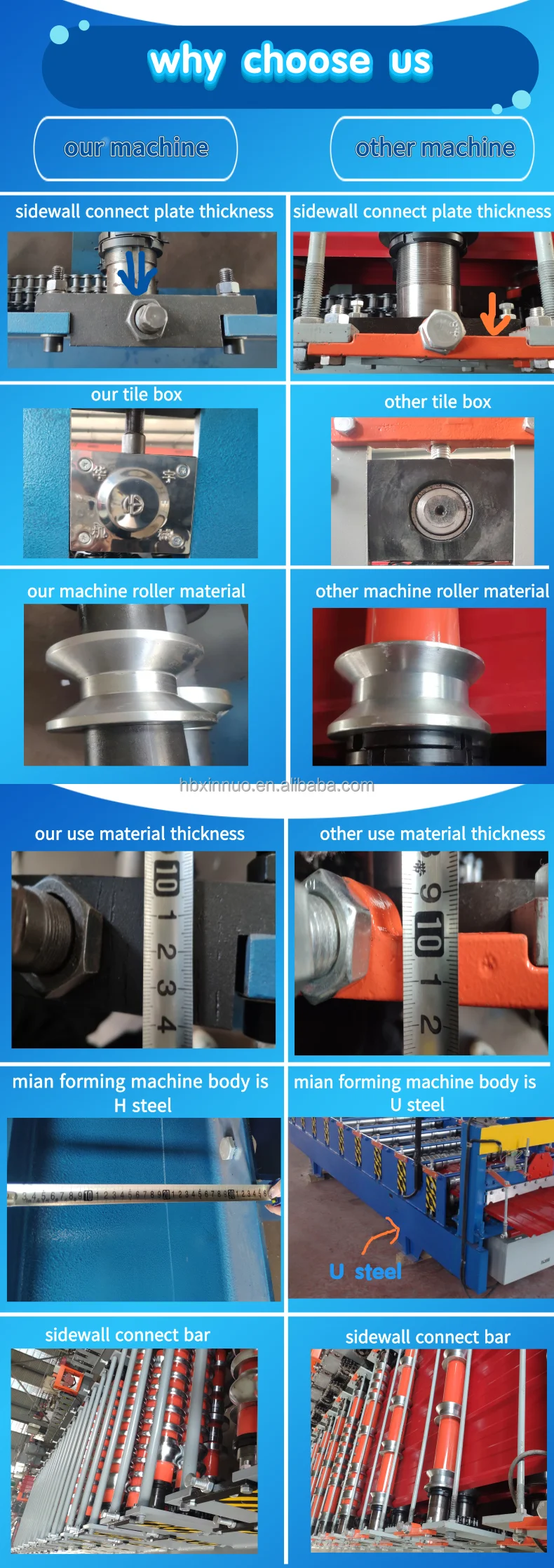

Main Frame

|

400mm H-Beam

|

|

4.

|

Total Power

|

22 kw

|

|

5.

|

Power Supply

|

380V, 3-Phase,50Hz

|

|

6.

|

Forming Speed

|

12-24m/min

|

|

7.

|

Roll Station

|

18 stands

|

|

8.

|

Roller Diameter

|

80mm

|

|

9.

|

Effective Width

|

80-300mm

|

|

10.

|

Feeding Thickness

|

1.5-3.0mm

|

|

11.

|

Backboard Thickness

|

20mm

|

|

12.

|

Cutter Standard

|

GCr12

|

|

13.

|

Roller Standard

|

Gcr15#

|

|

14.

|

Overall Size

|

About 8500×1000×1400mm

|

|

15.

|

Total Weight

|

About 10T

|

Packing & Delivery

|

Packaging Details:

|

Main machine is nude, the computer control box is packed with wooden frame.

|

|

Main machine is nude in the container, the computer control box is packed with wooden packaging.

|

|

|

Delivery Detail:

|

20 days

|

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

CZ purlin roll forming machine

-

gutter roll forming machine

-

garage door roll forming machine

-

double layer panel roll forming machine

-

automatic sheet decoiler machine tiles cutter m...

-

Automatic ceiling t-grids shaped steel bar fram...

-

automatic sheet decoiler machine tiles cutter m...

-

c profile steel roll forming machine auto c z s...

-

bending machine

-

corrugated panel roll forming machine

-

car panel roll forming machine

-

c purlin roll forming machine

-

cz purlin roll forming machine roll forming mac...

-

glazed tile roll forming machine

-

glazed tile roll forming machine drywall profil...

-

Hydraulic uncoiler