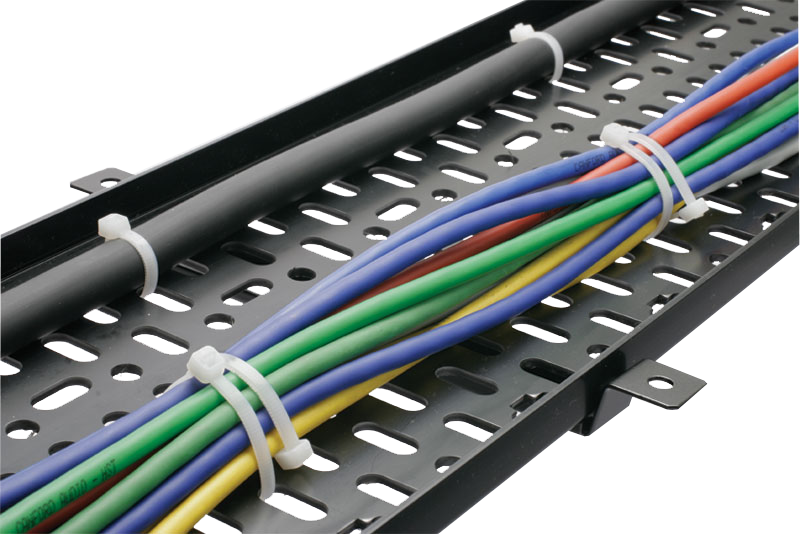

Revolutionize your cable tray production process with our state-of-the-art Cable Tray Cold Roll Forming Machine Line. Crafted to perfection, this high-end machinery seamlessly combines efficiency and precision, catering to your specific needs. Designed by a team of proficient engineers, this machine line is a game-changer in the world of cable tray manufacturing.

Revolutionize your cable tray production process with our state-of-the-art Cable Tray Cold Roll Forming Machine Line. Crafted to perfection, this high-end machinery seamlessly combines efficiency and precision, catering to your specific needs. Designed by a team of proficient engineers, this machine line is a game-changer in the world of cable tray manufacturing.

Efficiency Redefined:

With an unwavering commitment to boosting productivity, our Cable Tray Cold Roll Forming Machine Line ensures unrivaled efficiency. Featuring advanced technology, it enables you to produce cable trays at an astonishing pace, significantly reducing labor costs and maximizing your overall capacity. Say goodbye to time-consuming manual processes and embrace the power of automation.

Precision at its Finest:

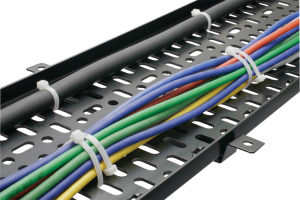

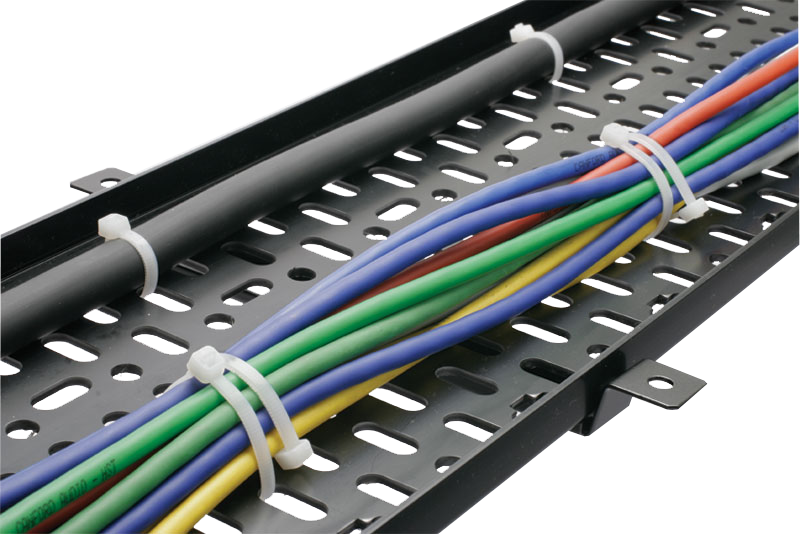

We understand the pivotal role precision plays in delivering top-notch cable trays. Our machine line is meticulously engineered to fabricate flawless cable trays with utmost accuracy. You can rely on its cutting-edge functionalities to consistently create cable trays that meet or even exceed your stringent quality standards. Every roll formed, every bend made, and every cut it executes adheres to precise measurements, ensuring a flawless end product.

Unmatched Adaptability:

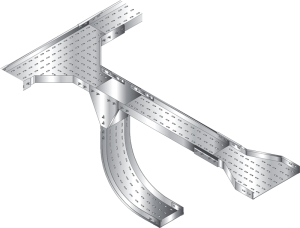

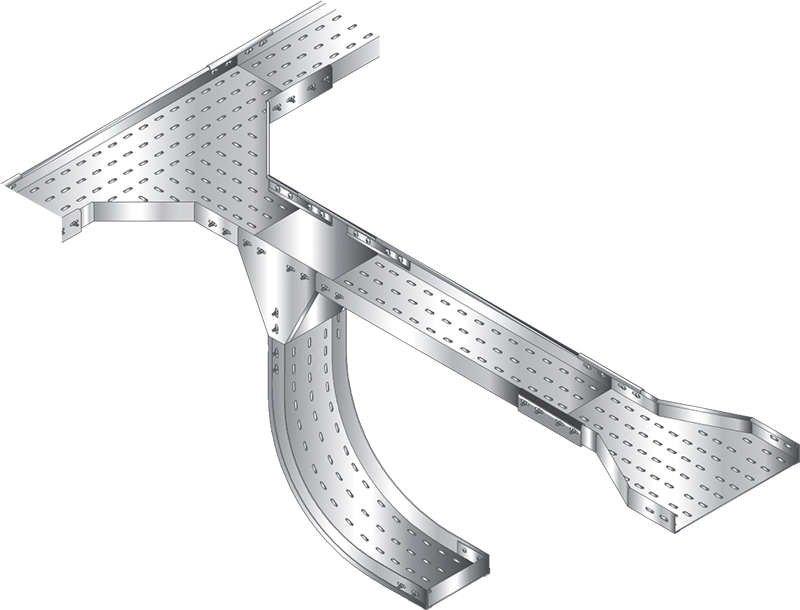

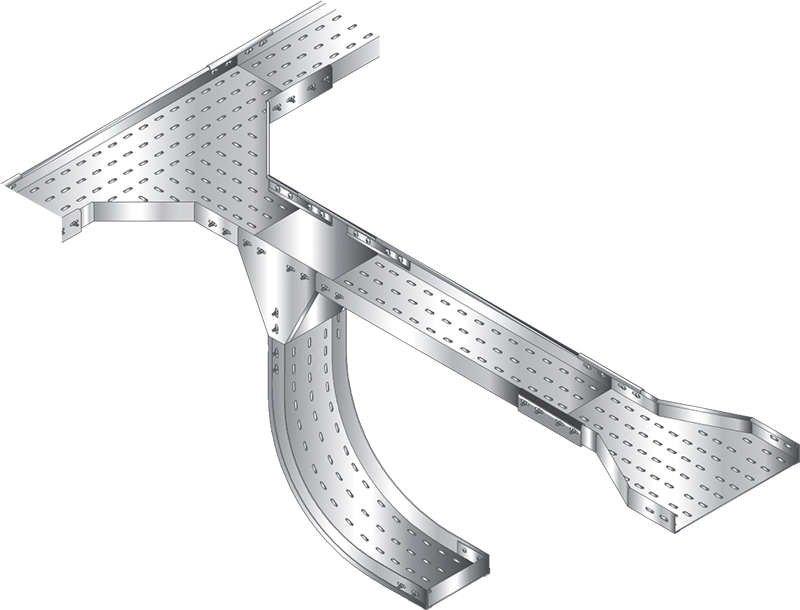

Embracing diverse manufacturing requirements, our Cable Tray Cold Roll Forming Machine Line offers unmatched adaptability. Whether you need cable trays of various sizes, shapes, or materials, this machine line caters to all your customization needs. Its adjustable features allow you to effortlessly switch between different tray dimensions, offering unparalleled versatility in your production process. Seamlessly adapt to ever-changing market demands and deliver tailored solutions to your customers.

High-End Technology:

Embodying the latest technological advancements, our Cable Tray Cold Roll Forming Machine Line stands as a testament to innovation. Equipped with an intuitive control system, it offers an effortless user experience, empowering your workforce to efficiently operate the machinery. Increase your production capacity and meet tight deadlines with this cutting-edge machinery that ensures seamless operations.

Reliability and Durability:

Investing in our Cable Tray Cold Roll Forming Machine Line guarantees long-term reliability and durability. Manufactured using high-quality materials, this machinery excels in durability, minimizing the likelihood of breakdowns or downtime. Benefit from its robust construction and rest assured that it will withstand challenging work environments, delivering consistent performance for years to come.

Perfect Solutions at Your Fingertips:

We take great pride in presenting you with the ultimate solution for cable tray production. Our Cable Tray Cold Roll Forming Machine Line offers unmatched speed, precision, versatility, and reliability that will take your business to new heights. Gain a competitive edge in the market with our cutting-edge machinery that not only meets but exceeds your expectations.

Upgrade your cable tray production process to a whole new level. Choose our Cable Tray Cold Roll Forming Machine Line and join a league of industry leaders who prioritize efficiency, precision, and customer satisfaction. Embrace the future of cable tray manufacturing today and experience unparalleled success.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

barrel corrugated roof sheet making machine sup...

-

Bottom beam of shutter door roll forming machine

-

C21 type tile press Roof panel roll forming mac...

-

double layer panel roll forming machine

-

garage door roll forming machine

-

garage doors machine herculift roller for sprin...

-

glazed tile roll making machine glazed and IBR ...

-

gutter roll forming machine

-

leveling machine

-

roller shutter door manufacturing wellding mac...

-

sandwich panels production machine line iron sh...

-

shutter door roll forming machine

-

slide rail roll forming machine

-

Stone Coated Steel Roof Panel Production Line

-

Xinnuo shutter door machine iron sheet rolling ...

-

automatic light keel making machine drywall u c...