-

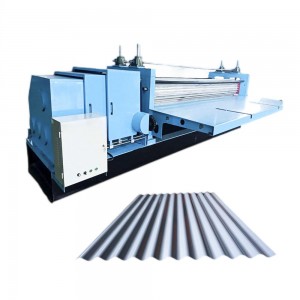

new arrival full automatic CNC roof sheet roll forming machine line

High-Speed, High-Volume Production:

Engineered specifically for efficient mass production of roofing corrugated sheets, siding panels, and floor decking.

Flexible Production Speeds:

Adjustable line speed from 20 to 60 meters per minute to match your output requirements.

Maximized Efficiency:

Integrated non-stop flying cut-off and fully automatic stacking system enables maximum line speeds up to 60 m/min with minimal downtime.

Quick Profile Changeover:

Cassette-type platform design allows for rapid switching between profiles, maximizing versatility for multi-profile production.

Quality & Compliance Assured:

Certified to European CE standards and backed by multiple international patents, guaranteeing performance and safety.

Raw Materials for Roof Panel Roll Forming Machine

·Suitable material: Colored Steel / Stainless Steel / Galvanized Steel / Aluminum Sheet

·Thickness: 0.3-0.8(mm)

·Width: 1200/1220/1250(mm) -

Double layer IBR and corrugated roofing sheet roll forming machine metal sheet making machine

We are manufacturers and designers of cold roll forming machines from China.

Products mainly include

Roof/Wall roll forming machine.

C/Z/U purlin roll forming machine.

EPS/Rock-wool sandwich panel roll forming machine production line.

Light steel frame machines and so on.

Based on 27 years of experience,We can supply you one-stop solution to fulfill all your needs in metal cold roll forming industry. -

standing seam panel roll forming machine

Standing seam panel roll forming machine is one of the major machines we are providing. With this roll former, panels are formed from color steel sheets with cold roll forming technique. The formed panels are widely applied in roof, wall, and other building parts. The cutters of the panel roll former are made from Cr12 molybdenumvanadium steel, showing high hardness and great wear resistance. Near 20 years’ rich manufacturing experience is a powerful guarantee of the quality of the Xinnuo roll forming machines. -

-

C21 type tile press Roof panel roll forming machine

Roof panel roll forming machine No. Main parameter of the machine for reference 1 Suitable to process Color steel plate 2 Width of the plate 850m 3 Thickness of the plate 0.3-0.8mm 4 De-coiler Manual one, can load 5 tons raw material 5 Rollers for forming 11rows 6 Diameter of the roller 70mm 7 Rolling material Carbon Steel 45# 8 Main motor power 4kw 9 Productivity 8-12m/min 10 Cutting method Hydraulic mould cutting 11 Material of the cut... -

-

-

double layer roll forming machine roll forming machine for steel profile drywall manufacturing machine

double layer roll forming machine roll forming machine for steel profile drywall manufacturing machine Product Description 836+840 double layer metal roofing sheet machine ♦Main Parameters: 1 Suitable to process Color steel plate, galvanized sheet, aluminum coils and etc. 2 Width of the feeding material 914-1250mm 3 Roller station 11-18 rows or custom as customer’s requirements 4 Thickness of feeding material 0.3-0.8mm 5 Productivity 8-12m/min 6 Rollers’ material... -

-

-

-

double layer roll forming machine roll forming machine for steel profile drywall manufacturing machine

double layer roll forming machine roll forming machine for steel profile drywall manufacturing machine Product Description 836+840 double layer metal roofing sheet machine ♦Main Parameters: 1 Suitable to process Color steel plate, galvanized sheet, aluminum coils and etc. 2 Width of the feeding material 914-1250mm 3 Roller station 11-18 rows or custom as customer’s requirements 4 Thickness of feeding material 0.3-0.8mm 5 Productivity 8-12m/min 6 Rollers’ material... -

-

roling machine double layer machine double layer glazed tile roll forming machine

Product Description 1 Suitable to process Color steel plate, galvanized sheet, aluminum coils and etc. 2 Width of the feeding material 914-1250mm 3 Roller station 11-18 rows or custom as customer’s requirements 4 Thickness of feeding material 0.3-0.8mm 5 Productivity 8-12m/min 6 Rollers’ material 45# steel 7 Diameter of shaft 70-... -

double layer roll forming machine roof sheet roll forming machine wellding Tile Making Machinery

double layer roll forming machine roof sheet roll forming machine wellding Tile Making Machinery Product Description 836+840 double layer metal roofing sheet machine ♦Main Parameters: 1 Suitable to process Color steel plate, galvanized sheet, aluminum coils and etc. 2 Width of the feeding material 914-1250mm 3 Roller station 11-18 rows or custom as customer’s requirements 4 Thickness of feeding material 0.3-0.8mm 5 Productivity 8-12m/min 6 Rollers’ material 45# ... -

-

-

-

-

Roll forming equipment supplier

More Than 30+ Years Manufacturing Experience

- info@hbxinnuorollforming.com

- 0086-15632788505