We pursue the management tenet of “Quality is superior, Service is supreme, Reputation is first”, and will sincerely create and share success with all clients for factory Outlets for Automatic Rain Water Steel Downpipe Cold Roll Forming Machine/Water Falling Down Gutter Making Machines, With us your money in secure your business in protected . Hope we can be your trustworthy supplier in China . Wanting forward for your cooperation .

We pursue the management tenet of “Quality is superior, Service is supreme, Reputation is first”, and will sincerely create and share success with all clients for China Roll Forming Machine and Tile Making Machine, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to deliver the high-quality products and solutions and services, and promote lasting cooperation with our customers, common development and create a better future.

*Detail

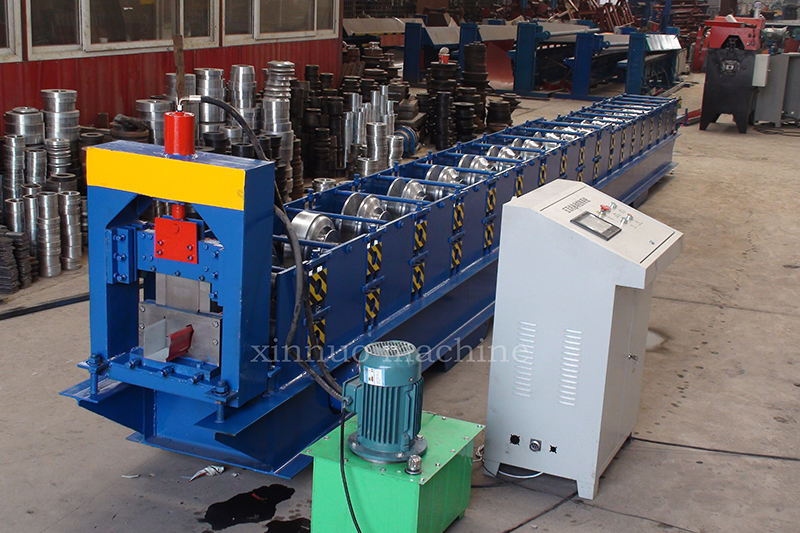

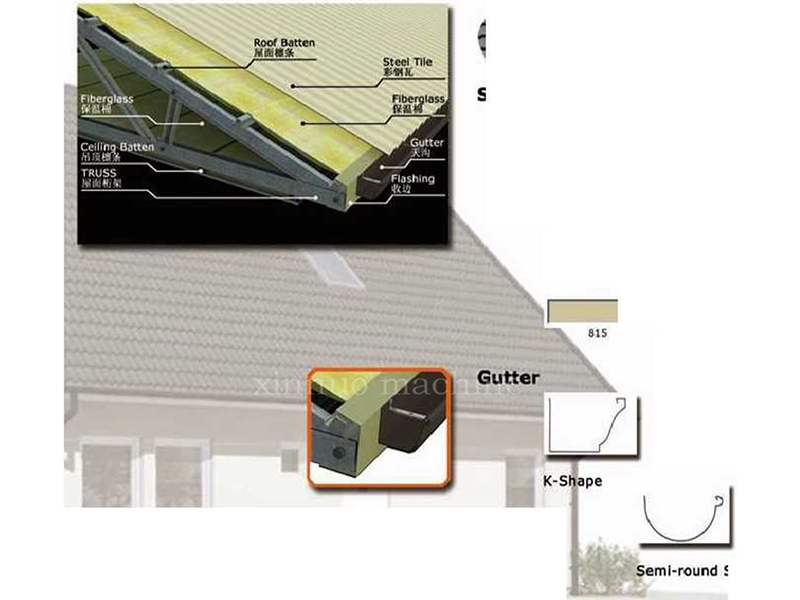

Rain Gutter equipment is the production of building roof gutter roll forming machine, the production of gutter refers to the building roof between the two hip concave part, used for house drainage.

Xinnuo Gutter roll forming machine is designed with a dimension of 8.2 *1.3*1.5m. It is distinguished for stable performance, high price/performance ratio, and easy operation. The gutter roll former in Xinnuo has been certified by CE. ISO, and TUV

Xinnuo has been developing and producing cold roll forming equipment since 1998. We are competent in customizing roll formers for clients according to their specific requirements and applications.

*Model:90type Rain gutter

| Configurations | Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Machine Of Roll Forming ,Electro-Motor,Cutting Device ,Hydraulic Station ,PLC Control, Supporter Table. |

| Control System | PLC Delta Inverter |

| Main Frame | 350mm H-Beam |

| Main Power | 4 kw |

| Pump Power | 3 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 8-16m/min |

| Roll Station | 18-22 stands |

| Roller Diameter | 70mm |

| Hydraulic Pressure | 10-12MPa |

| Forming Size | 90mm |

| Feeding Thickness | 0.3-0.8mm |

| Feeding Width | 160mm |

| Backboard Thickness | 14mm |

| Chain Size | 33mm |

| Cutter Standard | Cr12 |

| Roller Standard | Cr12 |

| Cr-Plating Size | 0.05mm |

| Overall Size | 8200×1000×1200mm |

| Total Weight | 5T |

All technical parameters can be changed,according to user s need.

*Details Pictures

*Application

Introducing the Steel Rain Gutter Cold Roll Forming Machine – The Ultimate Solution for Your Gutter System

Upgrade your gutter system with the state-of-the-art Steel Rain Gutter Cold Roll Forming Machine, designed to revolutionize your construction projects. This high-end machine is engineered with utmost precision to manufacture top-quality steel rain gutters effortlessly, ensuring durability and longevity for your building.

Sleek Design and Superior Durability:

Crafted with a sleek design, this machine guarantees a seamless and aesthetically pleasing finish for your rain gutters. Constructed with high-grade steel, it ensures exceptional strength, allowing it to withstand even the harshest weather conditions. Be it heavy downpours or extreme heat, this machine ensures your rain gutters will last for years to come.

Efficient Cold Roll Forming Technology:

Equipped with cutting-edge cold roll forming technology, this machine allows for the efficient manufacturing of rain gutters. The cold roll forming process ensures perfect shape retention, precise dimensions, and uniformity throughout the gutter length. Say goodbye to uneven and warped gutters – this machine guarantees consistent excellence every time.

Streamlined Operation and Increased Productivity:

Experience effortless operation with the user-friendly interface of this machine. Its intuitive controls make it easy for even the novice operators to quickly learn and operate it seamlessly. Minimize downtime and maximize productivity with its high-speed production capabilities. Save time and resources by producing a large volume of top-quality rain gutters in no time.

Versatility and Customization Options:

Cater to every customer’s unique requirements with the Steel Rain Gutter Cold Roll Forming Machine’s versatility and customization options. With adjustable settings, it allows you to produce rain gutters in various sizes, shapes, and profiles. From residential buildings to commercial establishments, this machine ensures a perfect fit for every project.

Unparalleled Precision and Accurate Measurements:

Delivering precision and accuracy, this machine guarantees consistent gutter dimensions every time. Its advanced measuring systems ensure that each rain gutter produced meets the exact specifications required. Rest assured that the gutters formed will fit seamlessly into any construction project, reducing installation time and effort.

Reliability and Low Maintenance:

Choose a machine that stands the test of time. The Steel Rain Gutter Cold Roll Forming Machine is built to last, offering unrivaled reliability. It boasts low maintenance requirements, allowing you to focus on your projects without worrying about frequent breakdowns or interruptions. Invest in a machine that promises longevity and consistent performance.

Safety Features for Peace of Mind:

Your safety is our priority. This machine comes equipped with top-notch safety features, ensuring a secure working environment. From emergency stop buttons to protective guards, it provides peace of mind for both operators and supervisors. Focus on your work with confidence, knowing that your team is protected.

In conclusion, the Steel Rain Gutter Cold Roll Forming Machine is the ultimate choice for a high-end, efficient, and reliable gutter manufacturing solution. Designed to meet the needs of both small and large-scale construction projects, this machine excels in delivering top-quality rain gutters. Invest in the future of your projects with this exceptional machine and experience the difference it brings to your gutter system.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

High Performance Stud Truss High Speed Light St...

-

Lowest Price for Double Layer Roll Forming Mach...

-

Wholesale OEM C Z Interchangeable Purline Roll ...

-

Super Lowest Price Xn Z-Lock Automatic EPS and ...

-

Super Lowest Price Factory Professional Galvani...

-

OEM/ODM Manufacturer EPS Roofing Wall Sandwich ...