As a way to ideal meet up with client’s desires, all of our operations are strictly performed in line with our motto “High Top quality, Competitive Cost, Fast Service” for Good quality Good Performance and Price Peb Automatic Changed C Purlin Cold Roll Forming Machine, “Passion, Honesty, Sound assistance, Keen cooperation and Development” are our targets. We are here anticipating mates all around the environment!

As a way to ideal meet up with client’s desires, all of our operations are strictly performed in line with our motto “High Top quality, Competitive Cost, Fast Service” for China C Purlin Forming Machine and Steel Forming Machine, Insisting on the high quality generation line management and customers pro assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We’ve been ready to face the worries and make the improve to understand all the possibilities in international trade.

*Detail

C purlin is widely applied in the purlin and wall beams of steel structures. It can be combined into lightweight roof truss, brackets, or other building components, as well as used for columns, beams, and arms in mechanical engineering.

Xinnuo has accumulated near 22 years’ experience in producing C purlin roll forming equipment. The C purlin roll former we made is distinguished for competitive price, high stability; and easy operation. It is designed with stepless shearing system, which allows the shearing for different dimensions of purlins to be done without the need of replacing cutter. The adjustment upon the bottom size is realized by increasing and reducing the spacers. About 3-4 hours are needed each time to change the purlin’s dimension.

*Features

1. The main feature of the C-purlin roll forming machine Is that its wheels and middle plate can be moved simply by adjusting the screw; and that operators can change the purlin’s dimension by regulating the screws on the side of the roll former.

2. Xinnuo has developed the fully automatic C purlin roll forming machine, which is controlled by computer to regulate the purlin’s dimension. The bottom size varies from 80mm to 300mm.

3. The c purlin roll former contributes both to save the time used for replacing cutters, and to cut on the labor cost.

4. For this roll former, all of the work involving size change is conducted automatically by computer. With the PLC control system, it will only take few minutes to change the purlin model and what operators have to do Is just to enter the instruction on the touch screen.

5. Shearing and punching devices are available to process the steel strips in advance so that they will not be wasted when replacing the purlin’s dimension.

6. For some cheap machine configuration, we recommend the C purlin roll former with flying saws, It comes at an affordable price and is competent in finishing the dimension change from 80mm to 300mm.

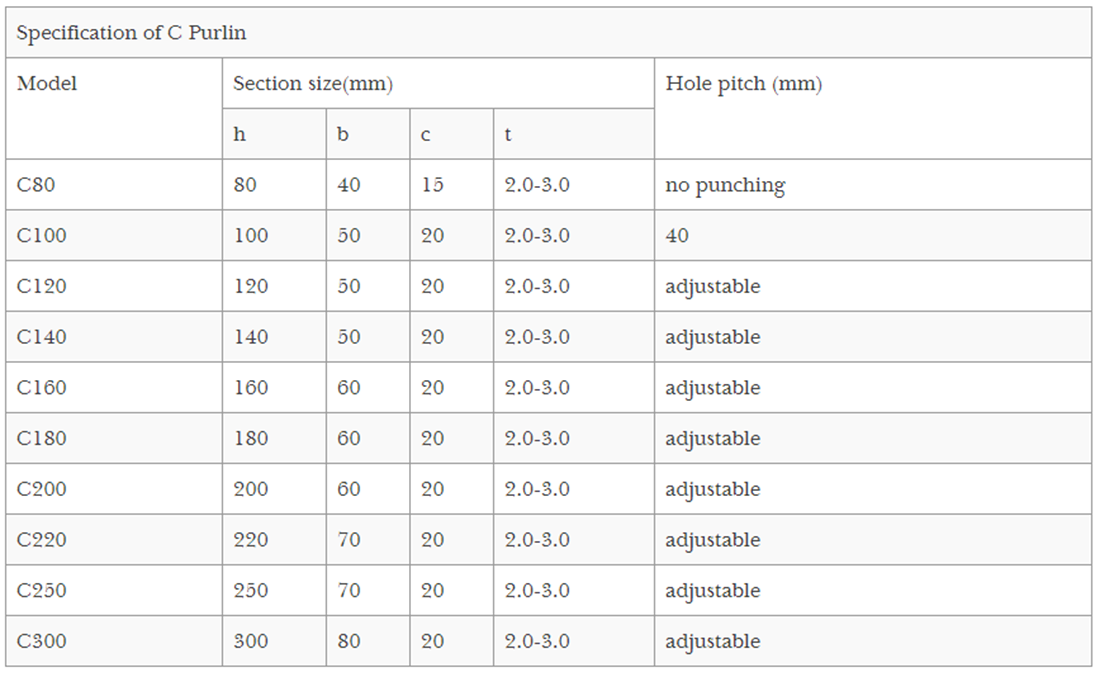

*Specification

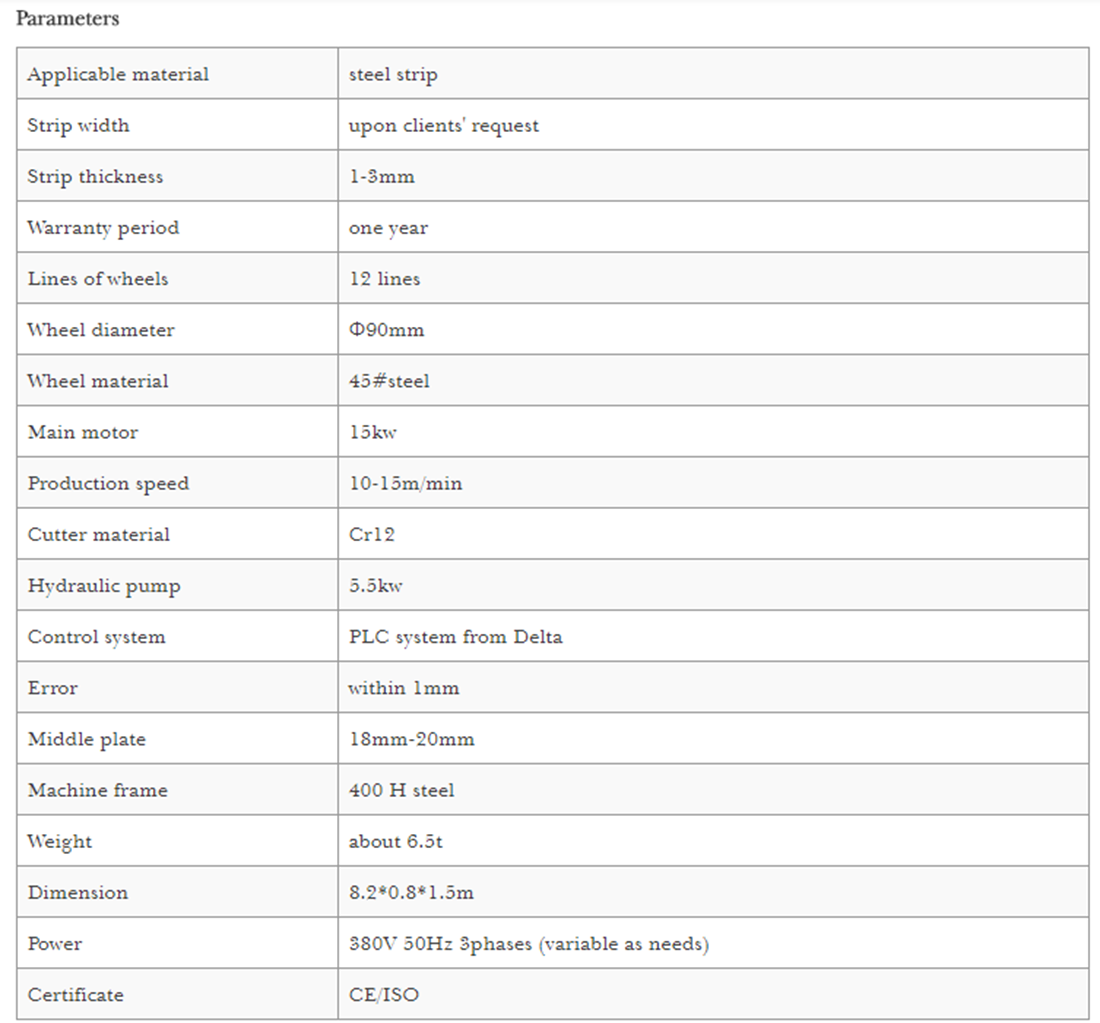

*Parameter

*Application

Introducing the C Purlin Roll Forming Machine, a revolution in the realm of steel construction. This high-end, state-of-the-art machine is designed with utmost precision and craftsmanship to meet the growing demands of the construction industry. Crafted by experts in the field, this machine embodies top-notch quality and unbeatable performance.

With our C Purlin Roll Forming Machine, your construction projects are bound to soar to new heights of excellence. Let’s delve into the impressive features that set this machine apart.

First and foremost, our machine is incredibly user-friendly. It comes equipped with a user-friendly interface that ensures hassle-free operations, even for beginners. Its intuitive controls allow for easy customization and adjustments, letting you effortlessly achieve desired specifications and dimensions.

This machine boasts exceptional speed and efficiency. With its advanced technology, it can swiftly produce flawless C purlins, ensuring a consistent and uniform shape every time. You’ll be amazed at the rapid production rate, saving both time and resources for your construction projects.

The rugged durability of the C Purlin Roll Forming Machine is truly noteworthy. Crafted from high-quality materials, it stands the test of time and guarantees long-lasting performance. You can rely on this machine to withstand heavy-duty usage, providing you with a reliable production solution for years to come.

We understand the importance of safety in any construction process. That’s why our C Purlin Roll Forming Machine is equipped with advanced safety features. From emergency stop buttons to protective covers, every aspect is meticulously designed to ensure a secure and protected working environment.

Customization is key in the modern construction industry, and our machine is here to cater to your unique needs. With adjustable settings, you have the flexibility to create a diverse range of C purlins, perfectly tailored to your project requirements. From size and shape to surface finish, the possibilities are endless.

Furthermore, our C Purlin Roll Forming Machine offers exceptional precision and accuracy. No more concerns about uneven edges or misplaced holes. This machine guarantees impeccable results, reducing the need for rework and enhancing the overall efficiency of your construction process.

We also understand the importance of space optimization in any workshop or construction site. The compact design of our machine ensures it fits seamlessly into your workspace, allowing for maximum productivity without compromise.

Investing in our C Purlin Roll Forming Machine means investing in unmatched excellence and unbeatable quality. Witness firsthand how this machine transforms your construction projects into remarkable feats of engineering.

In conclusion, the C Purlin Roll Forming Machine is a game-changer in the construction industry. Its user-friendly interface, exceptional speed, durability, safety features, customization options, precision, and compact design are just a few of the key features that make it a must-have for any construction professional. Don’t miss out on the opportunity to elevate your projects to new heights. Get your C Purlin Roll Forming Machine today and experience the epitome of efficiency and excellence.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

Wholesale OEM/ODM EPS and Rock Wool Roof and Cl...

-

Chinese wholesale Shutter Door Roll Forming Mac...

-

High Quality China Light Weight Block Making Ma...

-

xinnuo hot sale metal surface eps/rockwool inte...

-

Brazil new trend roof tile roll forming machine

-

Lowest Price for China Metal Steel Frame Profil...