We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Lowest Price for Rain Gutter Roll Forming Making Machine for Steel Structure, With our rules of ” organization track record, partner trust and mutual benefit”, welcome all of you to function together , improve jointly.

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for China metal gutter Roll Forming Machine and downpipe Forming Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade merchandise in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

*Detail

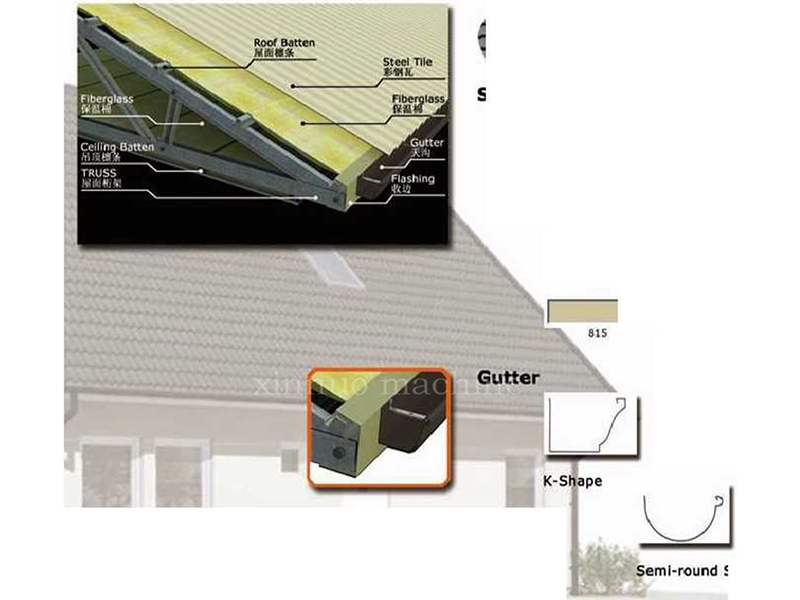

Rain Gutter equipment is the production of building roof gutter roll forming machine, the production of gutter refers to the building roof between the two hip concave part, used for house drainage.

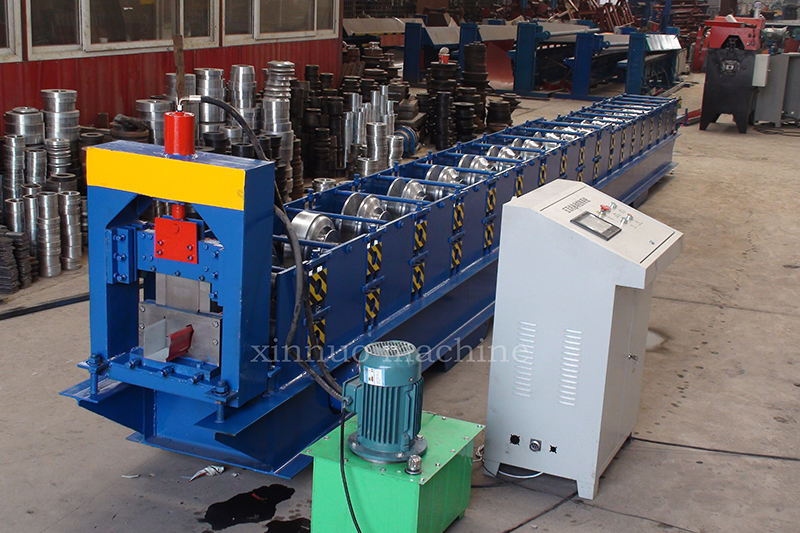

Xinnuo Gutter roll forming machine is designed with a dimension of 8.2 *1.3*1.5m. It is distinguished for stable performance, high price/performance ratio, and easy operation. The gutter roll former in Xinnuo has been certified by CE. ISO, and TUV

Xinnuo has been developing and producing cold roll forming equipment since 1998. We are competent in customizing roll formers for clients according to their specific requirements and applications.

*Model:90type Rain gutter

| Configurations | Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Machine Of Roll Forming ,Electro-Motor,Cutting Device ,Hydraulic Station ,PLC Control, Supporter Table. |

| Control System | PLC Delta Inverter |

| Main Frame | 350mm H-Beam |

| Main Power | 4 kw |

| Pump Power | 3 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 8-16m/min |

| Roll Station | 18-22 stands |

| Roller Diameter | 70mm |

| Hydraulic Pressure | 10-12MPa |

| Forming Size | 90mm |

| Feeding Thickness | 0.3-0.8mm |

| Feeding Width | 160mm |

| Backboard Thickness | 14mm |

| Chain Size | 33mm |

| Cutter Standard | Cr12 |

| Roller Standard | Cr12 |

| Cr-Plating Size | 0.05mm |

| Overall Size | 8200×1000×1200mm |

| Total Weight | 5T |

All technical parameters can be changed,according to user s need.

*Details Pictures

*Application

The Xinnuo gutter cold roll forming machine is a cutting-edge piece of equipment that revolutionizes the process of creating gutters for buildings. This machine utilizes cold roll forming technology, which allows for precise and efficient production of gutters with minimal waste. The intelligent design of the machine ensures that each gutter produced is of high quality, with consistent dimensions and a smooth finish. The advanced features of the Xinnuo gutter cold roll forming machine make it a valuable asset for any construction company looking to streamline their gutter manufacturing process.

One of the key benefits of the Xinnuo gutter cold roll forming machine is its versatility. This machine is capable of producing gutters of various sizes and profiles, making it suitable for a wide range of building projects. Additionally, the machine can be easily adjusted to accommodate different materials, allowing for flexibility in production. Its intelligent control system ensures that operators can easily program the machine to meet specific requirements, further enhancing its versatility and efficiency.

Overall, the Xinnuo gutter cold roll forming machine represents a significant advancement in gutter manufacturing technology. Its intelligent design, precision engineering, and versatility make it a valuable tool for construction companies looking to increase productivity and quality in their gutter production process. With the Xinnuo gutter cold roll forming machine, companies can expect to see improvements in both efficiency and profitability, making it a worthwhile investment for any construction business.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

-

factory Outlets for Colored Steel Roofing Glaze...

-

Newly Arrival China Roof Panel Roll Forming Mac...

-

High Quality China Light Weight Block Making Ma...

-

Factory Supply Gypsum Board Accessories Accesso...

-

2019 New Style Corrugated Cold Roll Steel Roof ...

-

Chinese wholesale China Roofing Tiles and Corru...