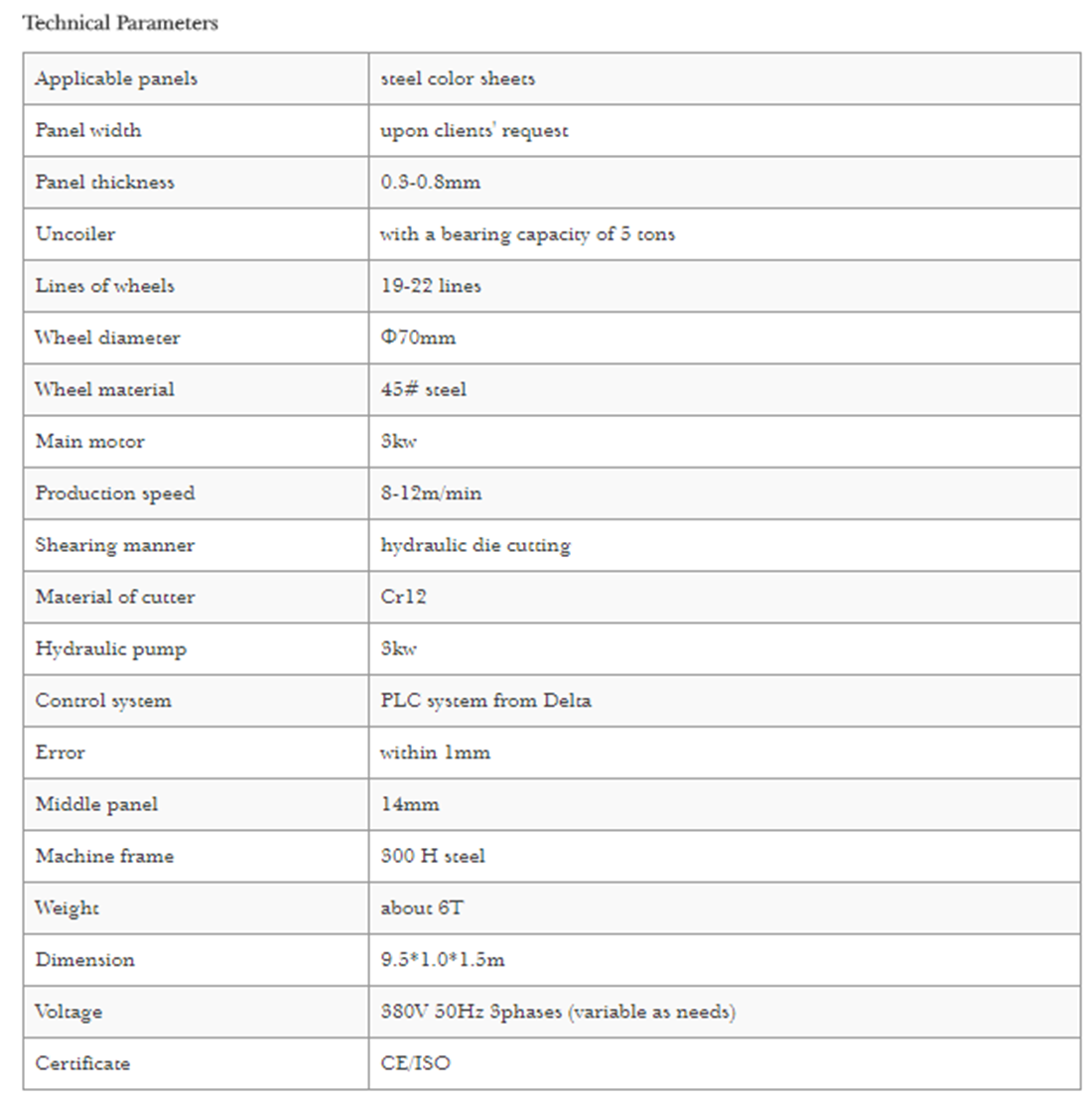

Metal Roofing Roll Forming Machine factory - standing seam panel roll forming machine – Xinnuo Detail:

*Detail

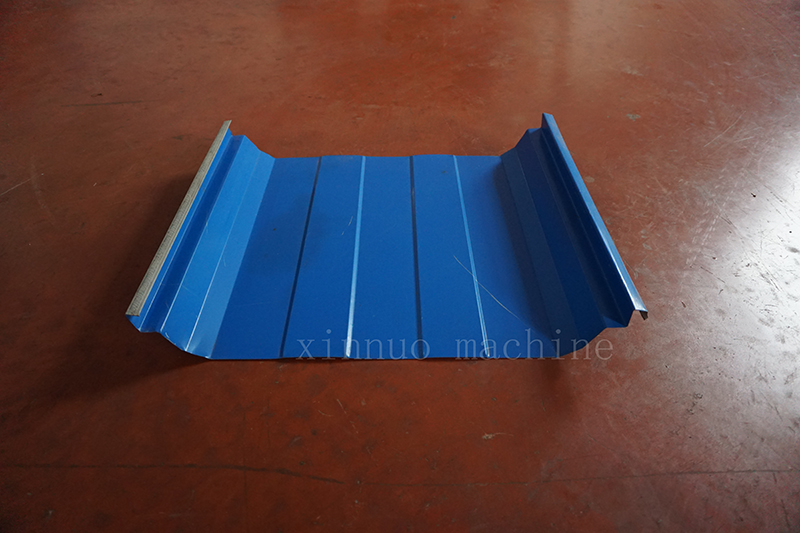

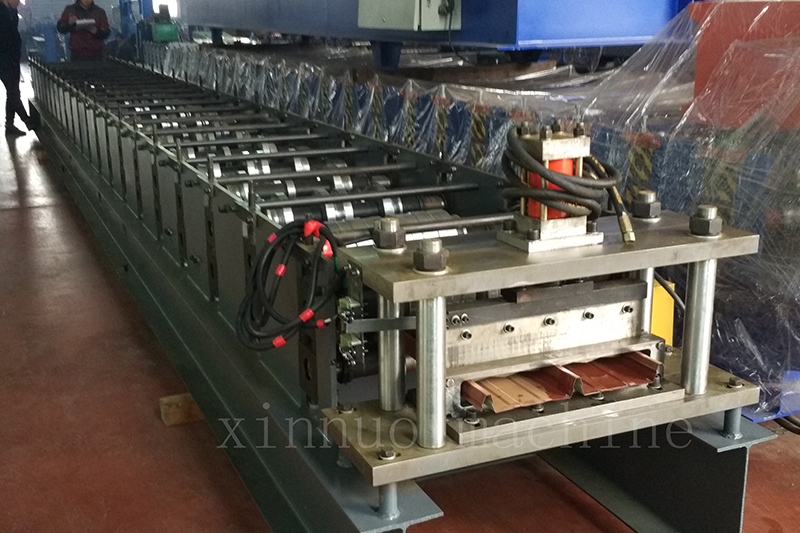

Standing seam panel roll forming machine is one of the major machines we are providing. With this roll former, panels are formed from color steel sheets with cold roll forming technique. The formed panels are widely applied in roof, wall, and other building parts. The cutters of the panel roll former are made from Cr12 molybdenumvanadium steel, showing high hardness and great wear resistance. Near 20 years’ rich manufacturing experience is a powerful guarantee of the quality of the Xinnuo roll forming machines.

*Sample

*Application

Product detail pictures:

Related Product Guide:

Our firm sticks to the basic principle of "Quality is the life of your company, and status will be the soul of it" for Metal Roofing Roll Forming Machine factory - standing seam panel roll forming machine – Xinnuo, The product will supply to all over the world, such as: Indonesia , Austria , United States , With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

2019 Latest Design Metal Forming Machines - c ...

-

New Fashion Design for Automatic Roll Forming M...

-

High Quality Metal Roll Forming Companies Facto...

-

Factory Cheap Hot Jupiter Roofing Machine - st...

-

high quality Roll Forming Machine Price priceli...

-

oem C Channel Roll Forming Machine quotes - c ...