SHENZHEN, China, Oct 13, 2022 (GLOBE NEWSWIRE) — BIGA Group has invested in an international standard technology platform and is one of the leading insulation panel companies in Vietnam. Eco-friendly materials are the industrial development trend in Vietnam. building sector.

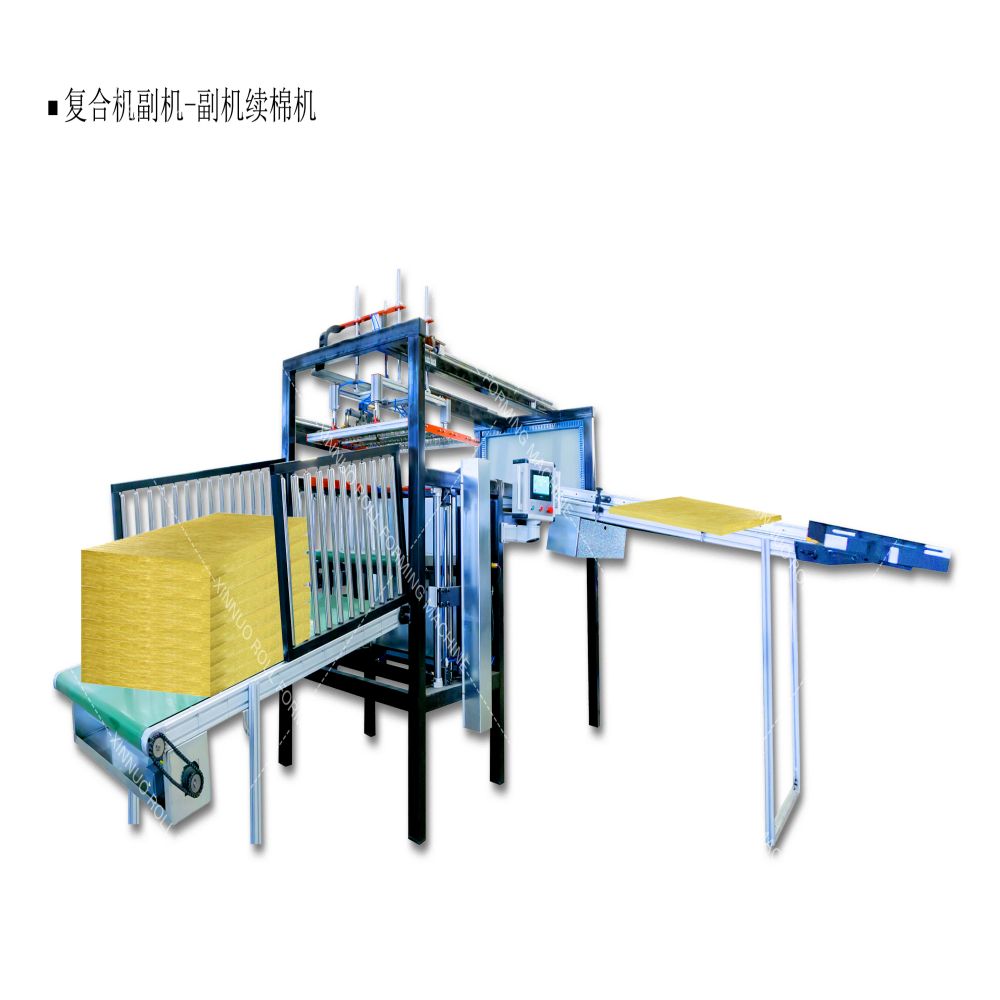

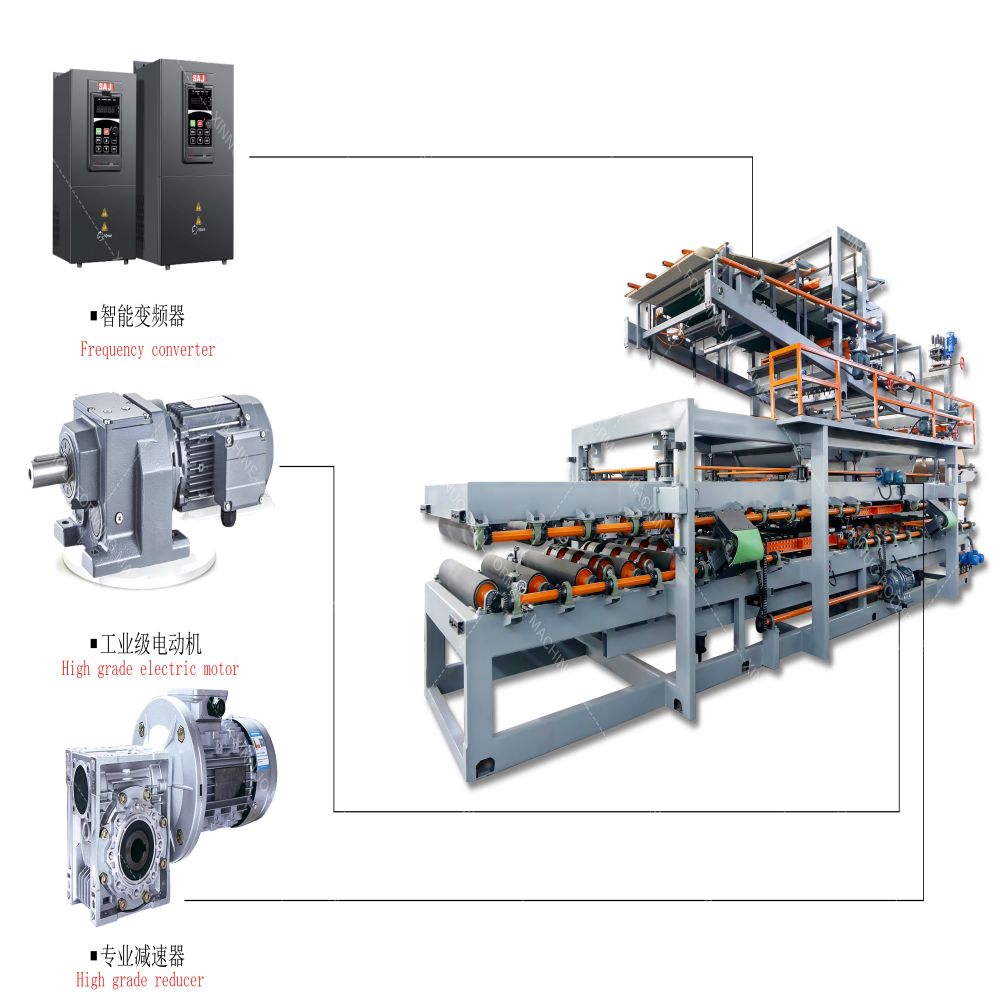

BIGA production lines are 100% imported from Korea, installed and operated by experienced Korean engineers. South Korea is known for more than 30 years of experience in the production, construction and application of panels – the use of this environmentally friendly material in industry and civil engineering. It is also the country in the world that sets the quality standards for panels.

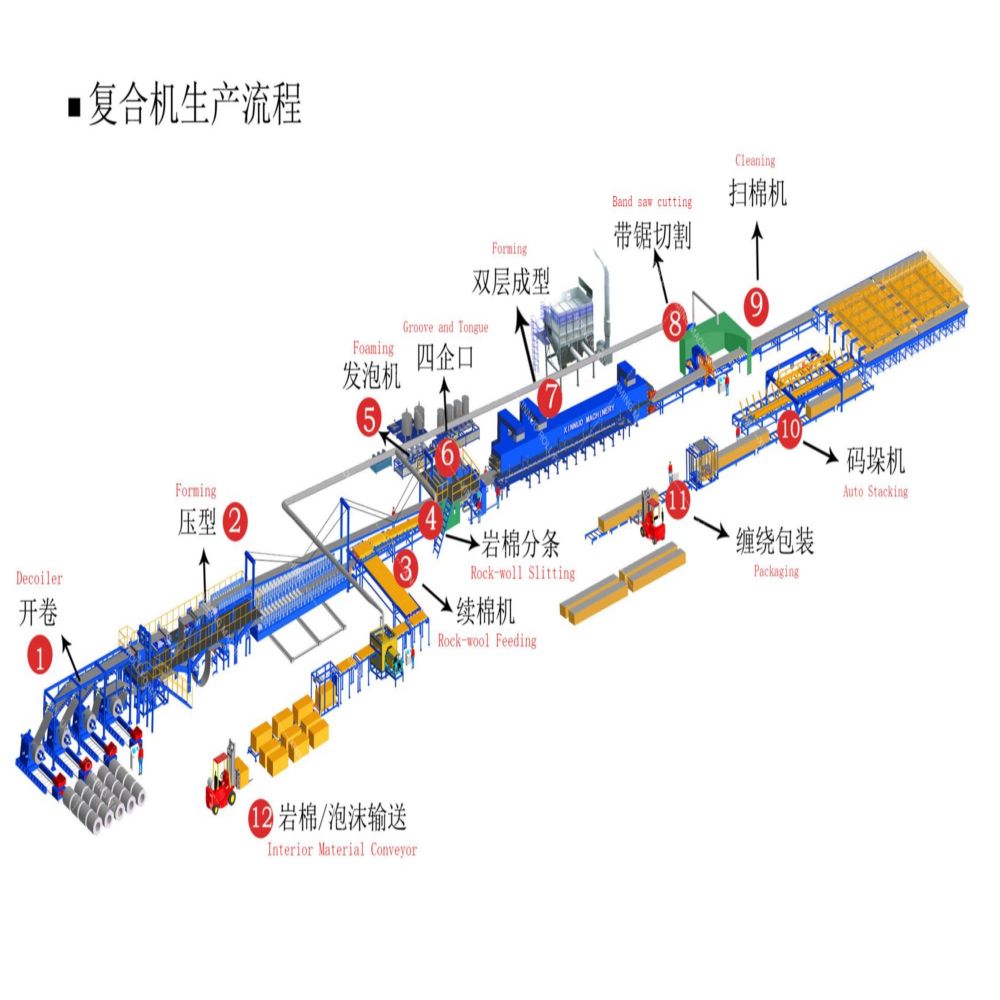

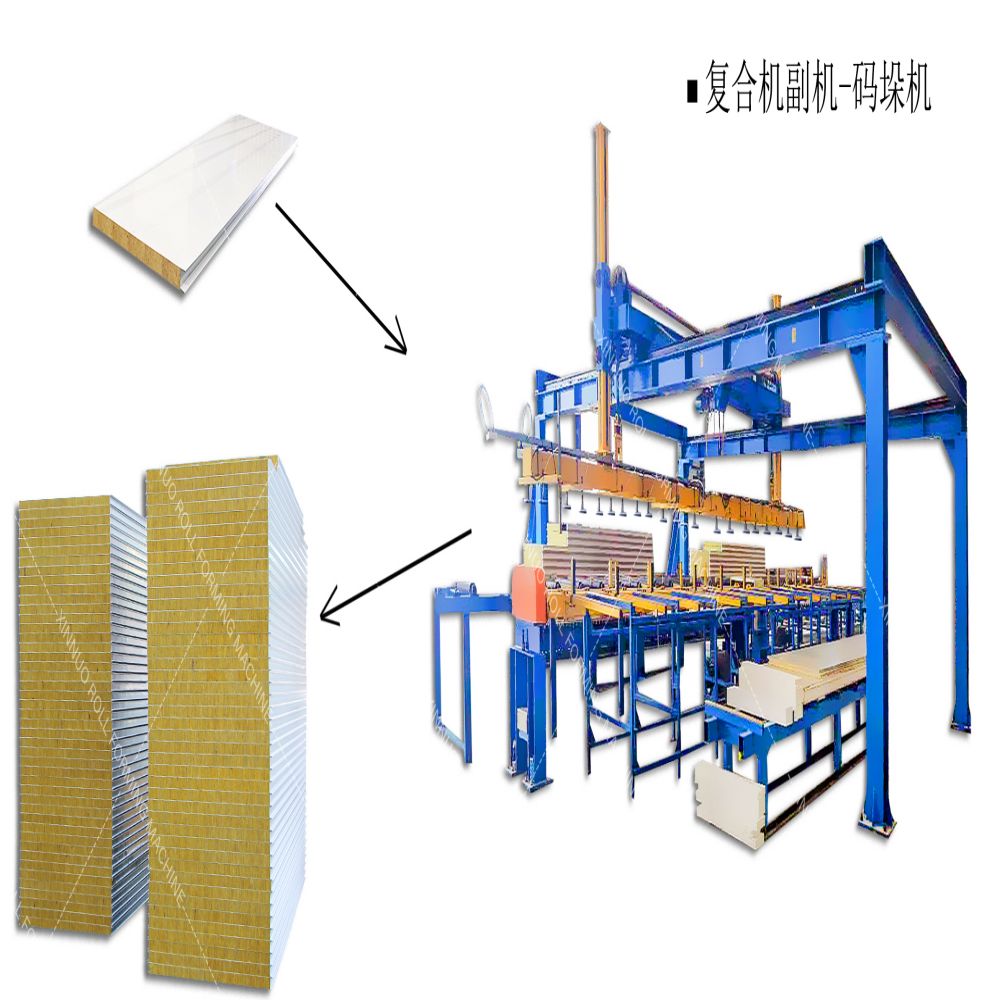

Modern high-performance equipment that meets international standards ensures the timely execution of dozens of projects simultaneously. BIGA sheets are produced in various ways, such as for roofs, wall panels, partition walls, ceiling panels, etc., and provide good performance in heat insulation, sound insulation, heat resistance, sound insulation and fire protection. North, BIGA PANEL is often mentioned as a supplier of branded and well-known panels, the first to be remembered by customers when it is necessary to build factories, warehouses, clean rooms, cold rooms.

Mr. Luu Wang Jang, General Manager of BIGA PANEL, said that in order to create insulating and heat-resistant panel products… “delight” discerning customers from Korea – the cradle of panels, in addition to Korean machines and technologies, BIGA PANEL from Korean standard raw materials .The selection is also “strict”, and the skills and qualifications of the technical team and production workers are constantly being improved.

From manufacturing to construction, by optimizing the value chain work model, proactively from factory systems, fleets to civil engineers, BIGA guarantees customer engagement. A comprehensive solution to achieve the goal of the project with an optimal budget.

The closed-loop process helps BIGA avoid waste at the production stage, optimize costs, and make construction costs more competitive, helping customers save costs significantly. From product quality to construction quality assurance, BIGA will also be more responsible. Make sure more commitments are met on schedule as BIGA is actively working from production, transportation to actual construction. ” – QS Division – Kovicons Construction Co., Ltd.

BIGA does not stop at an outstanding competitive advantage, and regularly conducts training activities to improve the attitude, thinking, safety and professional skills of all employees. The core values of “Discipline-Integrity-Devotion-Creativity-Love”, embedded and maintained in every person by BIGA, have “conquered” professional contractors from all over the world, such as Sungdo, Young Jin, Hanvina, KH vina… Foseca , Luxshare, Lucky Dragon, ITM, KMH, etc. are “special and strict” in terms of product quality and aesthetics.

“After many visits and inspections of BIGA factories, I chose BIGA because BIGA has a very neat and clean factory, and professionalism is reflected in the details,” Project Management, SUNGDO Contractor shared. With years of experience in building domestic brand BIGACONS, which has the largest market share in the construction of industrial sandwich panel plants in northern Vietnam, BIGA PANEL brand achieved a breakthrough in 2019. Become one of the most productive companies in Vietnam for the production of thermal insulation and refractory boards.

Post time: Nov-12-2022