Hebei Xinnuo Roll Forming Machinery Co., Ltd.: Empowering the High-Quality Development of the Roll Forming Equipment Industry with a Full Line of Composite Machines and Supporting Products

Hebei Xinnuo Roll Forming Machinery Co., Ltd., a professional manufacturer of roll forming machinery and equipment, comprehensively showcases its core product portfolio and service capabilities. Focusing on industry needs, the company has established a complete industrial service chain centered around composite machine production lines, supported by supporting equipment, raw materials, and accessories. This provides professional, integrated solutions for diverse scenarios such as construction, factories, hospitals, and warehouses, significantly promoting technological application and industrial upgrading in the roll forming equipment sector.

I. Core Product Line: Multi-Specification Composite Machine Production Lines Precisely Meet Diverse Production Needs

(I) Rockwool Foam Composite Machine Production Line (EPS/ROCK-WOOL SANDWICH PANEL PRODUCTION LINE)

(I) Rockwool Foam Composite Machine Production Line (EPS/ROCK-WOOL SANDWICH PANEL PRODUCTION LINE)

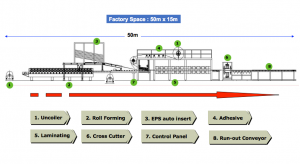

This production line offers a clear functional positioning and stable performance. In terms of material compatibility, the Z-Lock Sandwich Panel Production Line is highly compatible with both EPS (expandable polystyrene) and rock wool filling materials. It primarily produces roof panels and wall panels, and can customize product profiles to meet specific customer needs, meeting differentiated production requirements. The equipment comprises a feeder, forming machine, conveying system, uniform gluing system, laminating machine, discharge system, and receiving platform. Each component works in tandem to achieve fully automated operations from raw material processing to finished product output, ensuring both stable production efficiency and product quality.

(II) Z-Lock Sandwich Panel Production Line

As an upgraded core equipment model, it achieves breakthroughs in production capacity and material compatibility. In addition to compatibility with EPS and rock wool filling materials, it now also supports glass wool, further expanding its application scenarios. The product portfolio also focuses on roof panels and wall panels, while maintaining its advantage in profile customization. The equipment portfolio continues the established configuration of unloading machines, forming machines, conveying systems, uniform gluing systems, laminating machines, discharging systems, and receiving platforms. By optimizing production process design, the system adapts to larger-scale, more efficient production needs, providing customers with more competitive production solutions.

(III) Other Specialized Production Lines

The company has simultaneously deployed an insulation panel production line (BOX PANEL PRODUCTION LINE) and a Xinnuo EPS panel production line to enhance its product portfolio. The insulation panel production line fills a gap in specialized panel production equipment and enriches its composite panel product offerings. The Xinnuo EPS production line, with the foaming machine as its core equipment, integrates the EPS foaming machine and the PU foaming machine in the laminating machine’s auxiliary units, forming a complete technical chain for the production of specialized EPS products to meet the production needs of specific segments.

II. Supporting System: Comprehensive Equipment and Consumables Supply, Building an Integrated Service Closed Loop

(I) Supporting Equipment: Covering the Entire Production Process, Ensuring Operational Continuity

To ensure the efficient operation of the laminating machine production line, the company has established a comprehensive supporting equipment system. Among them, the packaging machine and auto stacker are responsible for packaging and neatly stacking finished products at the end of production, improving logistics and transportation efficiency. The four-sided flanging machine, rock wool feeding machine, and band saw, among other equipment, respectively handle key processes such as tongue and groove processing, rock wool conveying, and material cutting, ensuring seamless integration across all production links.

To meet the specialized needs of rock wool processing, the company has introduced a rock wool slitting machine and a rock wool cleaning machine. The former is equipped with imported blades and an industrial-grade motor to ensure precise slitting and stable cutting. The latter utilizes an industrial-grade motor and an industrial nylon long-bristled brush to effectively remove impurities from the rock wool surface, ensuring the cleanliness of the raw material. In addition, the laminating machine auxiliary equipment series includes pneumatic glue spreaders, EPS foaming machines, and PU foaming machines, providing specialized equipment support for core processes such as gluing and foaming, further enhancing production process stability

(II) Raw Materials and Accessories: A Full Range of Products Ensures Uninterrupted Production

In terms of raw material supply, the company covers all materials required for the entire composite board production process. Finished composite boards include two core categories: rock wool composite boards and foam composite boards, directly meeting customers’ end-product needs. The laminating machine’s supporting raw materials include glass wool, glue (including strong all-purpose glue and super glue), foam board, rock wool, and color rolls (including red envelope and white, etc.), ensuring high consistency between raw material quality and equipment compatibility.

In the accessories supply chain, the company provides key components such as industrial quartz heating tubes, gear oil pumps, and milling cutters. All are manufactured to industrial standards and meet the daily operation and maintenance requirements of laminating machine production lines, effectively reducing equipment failure rates and extending equipment life, providing a solid guarantee for customers’ production continuity. Hebei Xinnuo Tile Pressing Machinery Co., Ltd. has established a clear technological and service advantage in the roll-forming machinery and equipment sector with its comprehensive product portfolio and professional service capabilities. Through its integrated service model of “production line + supporting equipment + raw materials + accessories,” the company not only provides customers with efficient and stable production solutions but also leverages its expertise to drive technological advancements within the industry, injecting strong momentum into the high-quality development of the roll-forming equipment industry.

Post time: Aug-18-2025