Metal antique glazed tile roll forming machines are an essential tool in the manufacturing of antique glazed tiles, which are a popular choice for both residential and commercial buildings. These machines are specifically designed to create unique and intricate patterns on metal sheets, giving them a sophisticated and elegant finish. In this essay, I will delve deeper into the workings of a metal antique glazed tile roll forming machine, discussing its components, operation, benefits, and significance in the construction industry.

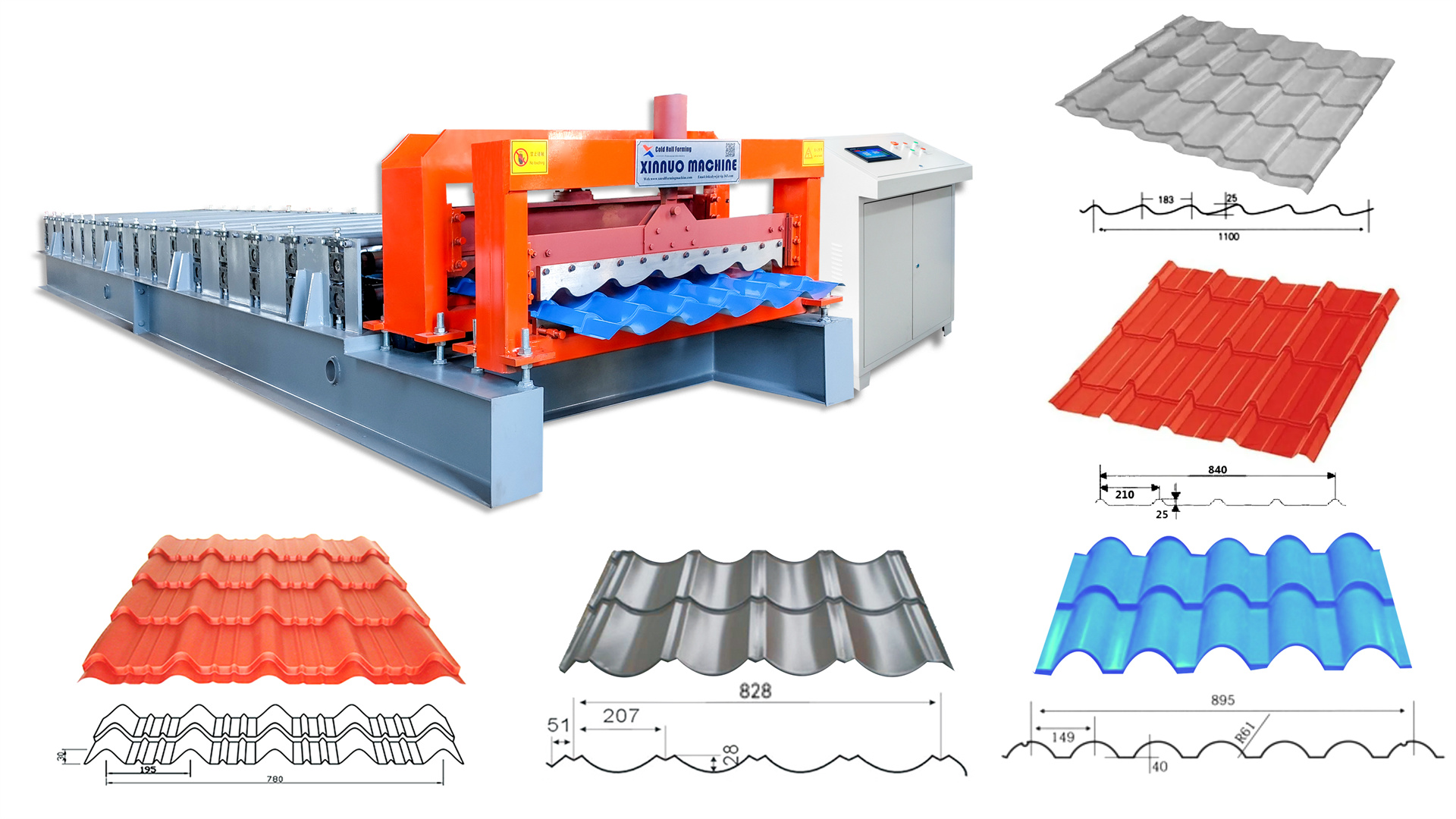

The metal antique glazed tile roll forming machine consists of several key components, including a decoiler, feeding device, roll forming system, hydraulic cutting system, and a control panel. The decoiler is responsible for feeding the raw metal sheets into the machine, while the feeding device ensures that the sheets are properly aligned and fed into the roll forming system. The roll forming system consists of a series of rollers that gradually shape the metal sheets into the desired pattern, while the hydraulic cutting system cuts the sheets into individual tiles. Finally, the control panel allows operators to adjust various settings and monitor the machine’s performance.

The operation of a metal antique glazed tile roll forming machine is relatively straightforward. Once the raw metal sheets are loaded onto the decoiler, they are fed into the machine and passed through the roll forming system. The rollers gradually shape the metal sheets into the desired pattern, creating a series of tiles with intricate designs. The hydraulic cutting system then cuts the tiles to the desired length before they are collected and stacked for further processing. The entire process is automated and can be easily controlled by operators using the control panel.

One of the primary benefits of using a metal antique glazed tile roll forming machine is its efficiency and accuracy. These machines are capable of producing a large number of tiles in a short amount of time, ensuring that construction projects are completed quickly and efficiently. Additionally, the precision of the roll forming system ensures that each tile is uniform in size and shape, resulting in a high-quality finished product. This not only enhances the overall aesthetic appeal of the tiles but also improves their durability and longevity.

Metal antique glazed tile roll forming machines are also significant in the construction industry due to their versatility and adaptability. These machines can be easily customized to create a wide range of tile designs, allowing manufacturers to cater to the diverse preferences of their customers. Furthermore, the use of metal sheets provides additional strength and durability to the tiles, making them ideal for both interior and exterior applications. The unique glazed finish adds a touch of elegance and sophistication to any building, making them a popular choice among architects and designers.

In conclusion, metal antique glazed tile roll forming machines play a crucial role in the manufacturing of high-quality antique glazed tiles. Their precision, efficiency, versatility, and durability make them an invaluable tool in the construction industry, allowing manufacturers to create unique and sophisticated designs with ease. By understanding the workings of these machines and their significance in the industry, we can appreciate the craftsmanship and attention to detail that goes into producing these beautiful tiles.

Post time: May-20-2024