The roofing industry has seen significant advancements in technology and innovation over the years, with one of the most noteworthy being the development of the portable metal roofing roll forming machine. This remarkable machine has revolutionized the standing seam roofing system, offering unprecedented levels of efficiency, precision, and versatility.

The portable metal roofing roll forming machine is designed to fabricate custom-made metal roofing panels on site, eliminating the need for prefabricated panels that require extensive transportation and handling. This not only reduces the overall cost of the roofing project but also significantly shortens the construction timeline. The machine’s portability also allows it to be easily transported to various job sites, making it an ideal choice for both commercial and residential projects.

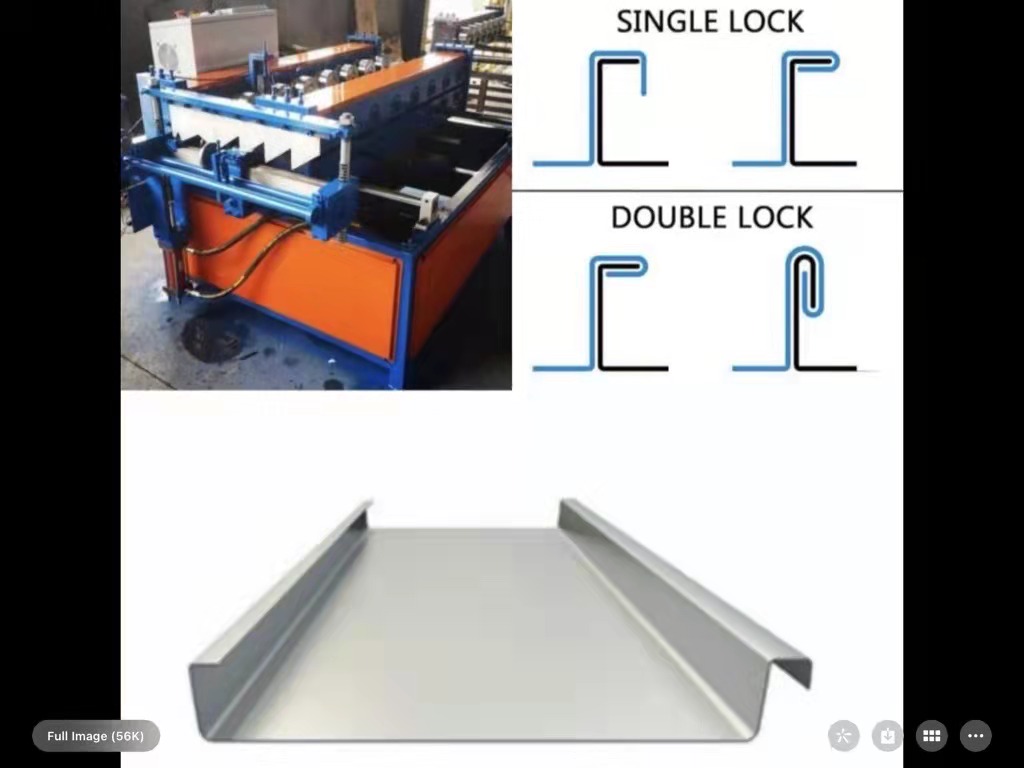

The standing seam roofing system is a popular choice among architects and builders due to its aesthetic appeal and durability. The system consists of long, interlocking metal panels that are secured to the roof deck with concealed fasteners. The interlocking seams create a watertight barrier that resists leaks and wind uplift, making it an ideal solution for areas with extreme weather conditions.

The portable metal roofing roll forming machine is specifically designed to fabricate these standing seam panels with precision and efficiency. The machine rolls out the metal material into the desired shape and size, forming a continuous panel that is ready to be installed on the roof. The machine’s adjustable settings allow it to accommodate different material thicknesses and widths, providing maximum flexibility and versatility.

One of the key benefits of using the portable metal roofing roll forming machine is the reduction in waste and material costs. Since the panels are fabricated on site, there is no need to overbuy or stockpile prefabricated panels. This not only reduces the overall cost of the project but also minimizes the environmental impact by reducing waste.

The machine’s ease of use and operator-friendly design make it a popular choice among contractors and roofing professionals. The machine requires minimal setup and can be operated by a single operator, further reducing labor costs and increasing productivity. The machine’s durable construction and long-lasting components ensure reliable performance even under harsh working conditions.

In conclusion, the portable metal roofing roll forming machine has revolutionized the standing seam roofing industry by providing unprecedented levels of efficiency, precision, and versatility. Its ability to fabricate custom-made metal roofing panels on site has reduced costs, shortened construction timelines, and minimized waste. The machine’s ease of use and operator-friendly design have made it a popular choice among contractors and roofing professionals, while its durable construction ensures reliable performance for years to come.

The future of the roofing industry looks bright with the continued development and innovation of portable metal roofing roll forming machines. As technology continues to advance, we can expect even more efficient and versatile machines that will further revolutionize the roofing industry and meet the demands of today’s modern construction projects.

Post time: Feb-28-2024