Lightgage Steel Joist Keel is a innovative structural component that has revolutionized the construction industry with its superior strength, design flexibility, and cost-effectiveness. This article provides a comprehensive overview of Lightgage Steel Joist Keel, exploring its history, advantages, design and construction processes, installation methods, applications across different sectors, as well as maintenance and sustainability considerations. By comparing this modern solution with traditional joist systems and discussing future trends in technology, readers will gain valuable insights into the benefits and potential of Lightgage Steel Joist Keel in modern construction practices.

Introduction to Lightgage Steel Joist Keel

Definition and Purpose

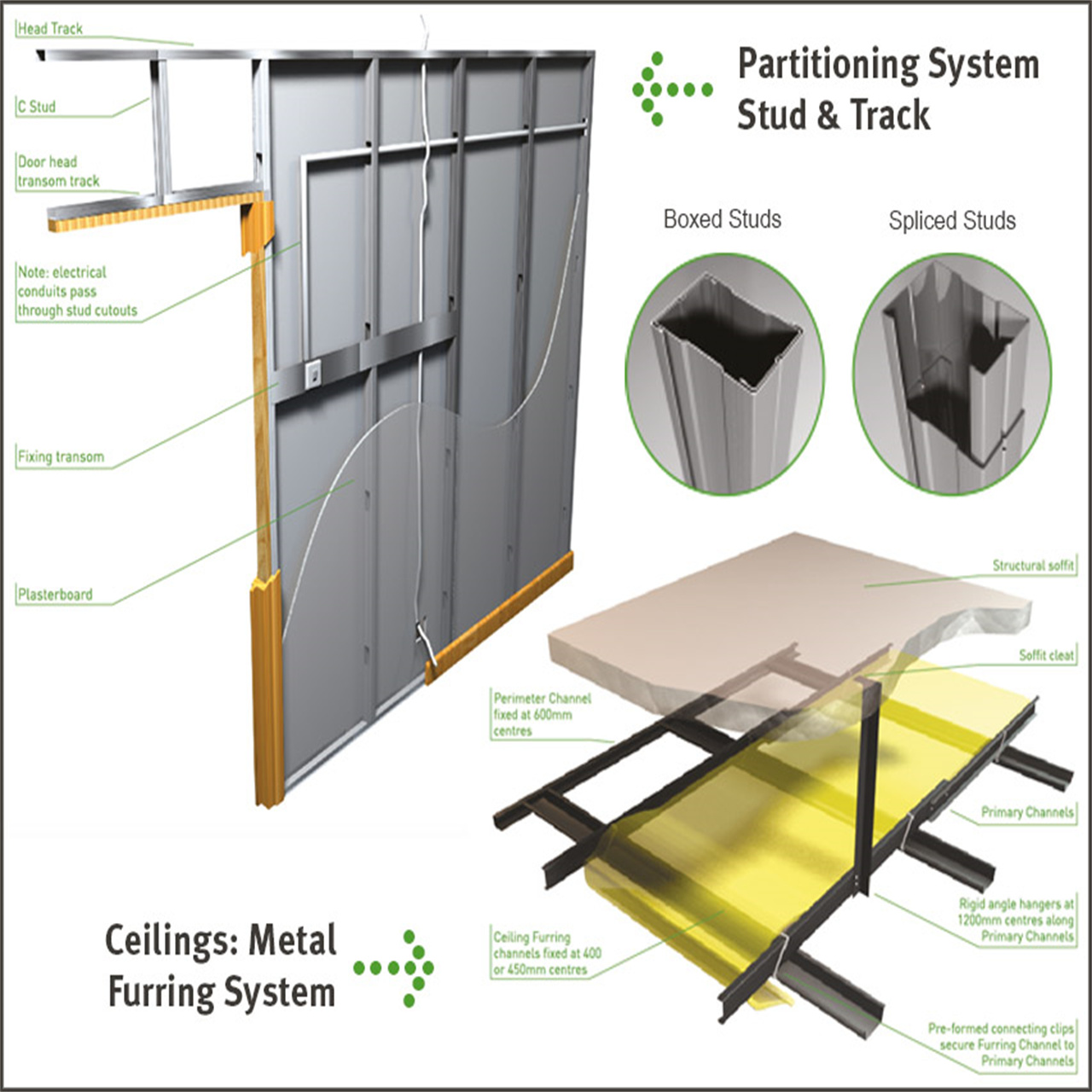

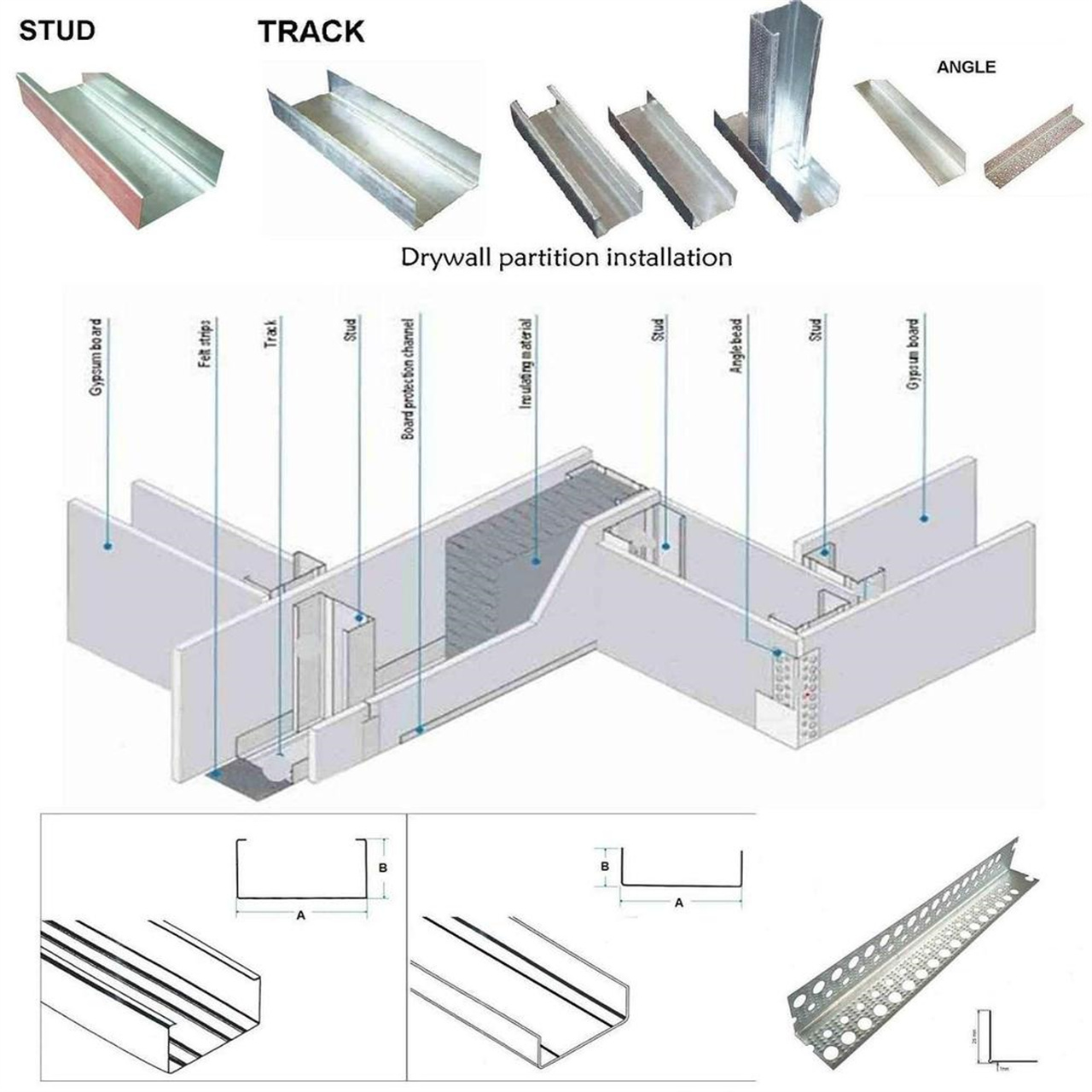

Lightgage steel joist keel is a structural component used in construction to provide support for floors, ceilings, and roofs. Its primary purpose is to serve as a lightweight and efficient framing solution that offers strength and stability to a structure.

History and Development

Initially developed in the early 20th century, lightgage steel joist keel has evolved over time to become a popular choice in modern construction. Its design and manufacturing processes have been refined to meet the increasing demands for cost-effective and durable building materials.

Advantages of Lightgage Steel Joist Keel

Strength and Durability

Lightgage steel joist keel offers excellent strength and durability, making it ideal for withstanding heavy loads and adverse weather conditions. Its high tensile strength and resistance to corrosion contribute to its long-lasting performance.

Cost-Effectiveness

One of the key advantages of lightgage steel joist keel is its cost-effectiveness. Compared to traditional building materials, such as wood or concrete, it is more affordable to manufacture, transport, and install. This cost efficiency makes it a preferred choice for many construction projects.

Design Flexibility

Lightgage steel joist keel provides architects and engineers with greater design flexibility due to its lightweight nature and customizable dimensions. It can be easily shaped and formed to fit specific project requirements, allowing for creative and innovative construction solutions.

Design and Construction of Lightgage Steel Joist Keel

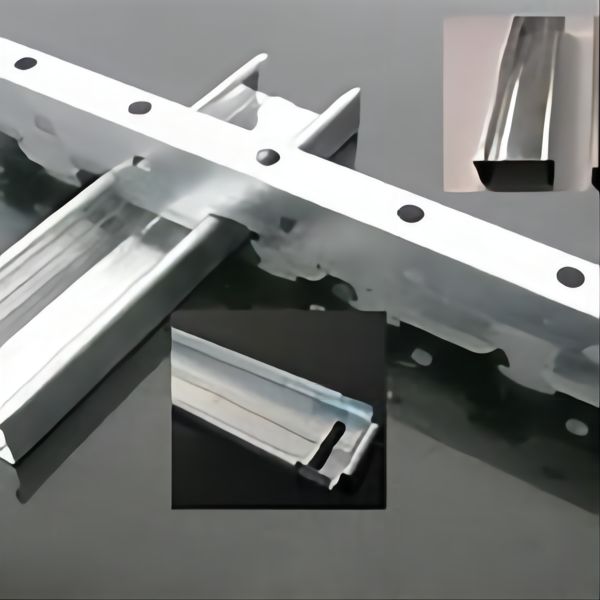

Material Composition

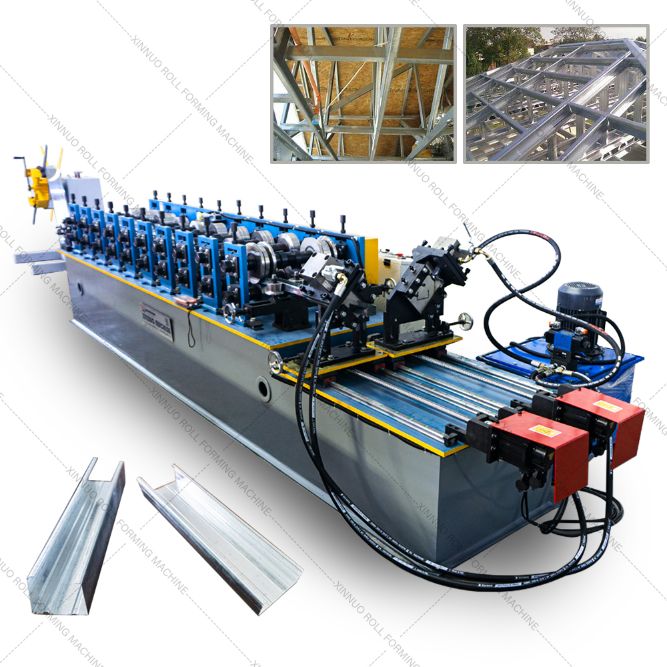

Lightgage steel joist keel is typically made from cold-formed steel sheets that are precision-engineered to meet industry standards. The use of high-quality steel ensures the structural integrity and reliability of the joist keel in various building applications.

Engineering Considerations

When designing lightgage steel joist keel, engineers take into account factors such as load-bearing capacity, deflection limits, and seismic requirements. By conducting thorough structural analysis and calculations, they ensure that the joist keel meets safety and performance standards.

Manufacturing Process

The manufacturing process of lightgage steel joist keel involves roll-forming steel coils into the desired shape and size. Precision cutting and punching techniques are used to create openings for mechanical connections and fittings. Quality control measures are implemented to guarantee the consistency and accuracy of each joist keel produced.

Installation Process of Lightgage Steel Joist Keel

Pre-Installation Preparation

Before installing lightgage steel joist keel, it is essential to plan and prepare the work area accordingly. This includes verifying dimensions, ensuring proper alignment, and assessing site conditions to prevent any potential issues during installation.

Step-by-Step Installation Guide

1. Position the joist keel at the designated locations, ensuring proper spacing and alignment.

2. Secure the joist keel in place using appropriate fasteners and connectors according to manufacturer specifications.

3. Verify the levelness and stability of the installed joist keel to ensure structural integrity.

4. Repeat the installation process for additional joist keel sections, following the structural design plans.

5. Conduct a final inspection to confirm that the installation meets safety and quality standards before proceeding with further construction activities.

Applications of Lightgage Steel Joist Keel

Residential Construction

Lightgage steel joist keel is gaining popularity in residential construction for its lightweight yet sturdy structure, making it ideal for framing floors, ceilings, and roof systems in homes. Its flexibility and ease of installation make it a cost-effective choice for various residential projects.

Commercial and Industrial Buildings

In commercial and industrial buildings, lightgage steel joist keel offers exceptional strength and durability, making it a preferred choice for supporting heavy loads and creating open and spacious interiors. It is commonly used in warehouses, retail spaces, and industrial facilities due to its efficiency and long-term performance.

Maintenance and Sustainability of Lightgage Steel Joist Keel

Maintenance Best Practices

Maintaining lightgage steel joist keel is relatively simple, requiring periodic inspections for any signs of corrosion or damage. Regular cleaning and addressing any issues promptly can help prolong its lifespan and ensure structural integrity.

Sustainability Benefits

Lightgage steel joist keel is a sustainable building material as it is recyclable, reducing waste and environmental impact. Its efficient use of materials and energy during manufacturing and construction also contributes to green building practices, making it a preferred choice for environmentally conscious projects.

Comparison with Traditional Joist Systems

Strength and Performance

Compared to traditional joist systems, lightgage steel joist keel offers superior strength and performance, with higher load-carrying capacities and better resistance to fire, rot, and pests. Its lightweight design also allows for longer spans and greater design flexibility, enhancing overall structural integrity.

Cost Comparison

While the initial cost of lightgage steel joist keel may be slightly higher than traditional joist systems, its long-term durability and minimal maintenance requirements result in cost savings over the lifespan of the structure. Additionally, its ease of installation can reduce labor costs and construction time, making it a cost-effective choice in the long run.

Future Trends in Lightgage Steel Joist Keel Technology

Innovations in Design and Materials

The future of lightgage steel joist keel technology lies in continuous innovations in design and materials, including advancements in coatings for improved corrosion resistance, sustainable manufacturing practices, and digital modeling for enhanced structural performance.

Industry Adoption and Growth Prospects

As the construction industry continues to emphasize efficiency, sustainability, and cost-effectiveness, the adoption of lightgage steel joist keel is expected to grow significantly. With ongoing research and development, this technology is poised to revolutionize modern construction practices and play a key role in shaping the buildings of tomorrow.In conclusion, Lightgage Steel Joist Keel stands out as a versatile and reliable solution for structural support in various construction projects. With its numerous advantages, from strength and durability to design flexibility and sustainability, this innovative component is shaping the future of construction practices. As industry trends continue to evolve and technologies advance, the potential for Lightgage Steel Joist Keel to play an even more prominent role in the built environment is promising. Embracing this modern approach can lead to enhanced efficiency, longevity, and cost savings, making it a valuable asset for architects, engineers, and builders alike.

FAQs about Lightgage Steel Joist Keel

1. What are the main advantages of using Lightgage Steel Joist Keel in construction projects?

2. How does the installation process of Lightgage Steel Joist Keel differ from traditional joist systems?

3. What are some common applications of Lightgage Steel Joist Keel in residential and commercial construction?

4. Are there any special maintenance considerations for Lightgage Steel Joist Keel to ensure its longevity and performance?

Post time: Mar-21-2024