The Xinnuo self clip lock standing seam roof panel cold roll forming machine is a cutting-edge innovation in the field of roofing construction. This state-of-the-art machinery has revolutionized the way standing seam roof panels are manufactured, offering unparalleled efficiency, precision, and quality. In this article, we will delve into the key features, benefits, and applications of this advanced equipment.

The Xinnuo self clip lock standing seam roof panel cold roll forming machine is a cutting-edge innovation in the field of roofing construction. This state-of-the-art machinery has revolutionized the way standing seam roof panels are manufactured, offering unparalleled efficiency, precision, and quality. In this article, we will delve into the key features, benefits, and applications of this advanced equipment.

1. Understanding the Xinnuo Self Clip Lock Standing Seam Roof Panel Cold Roll Forming Machine:

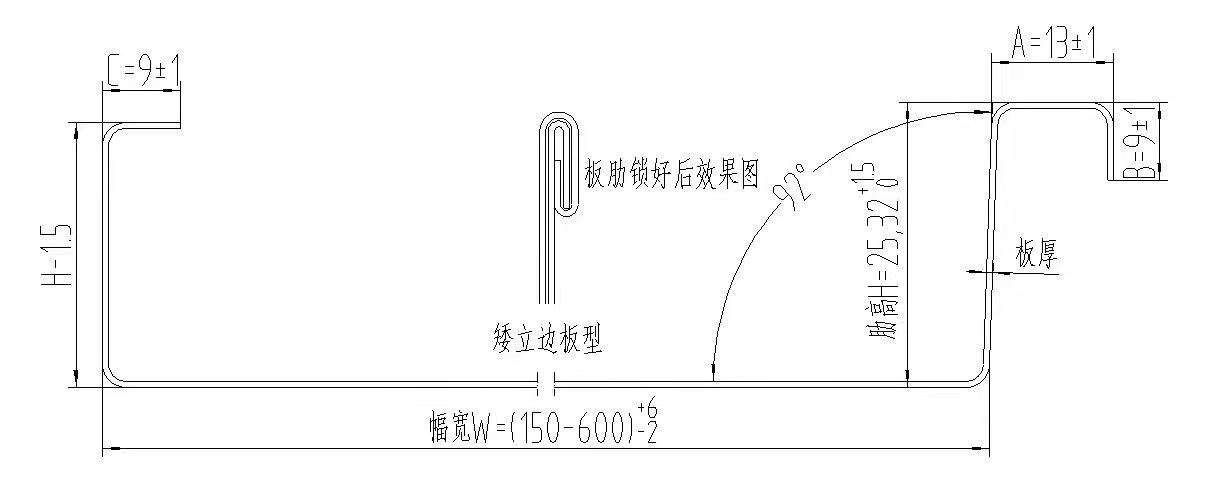

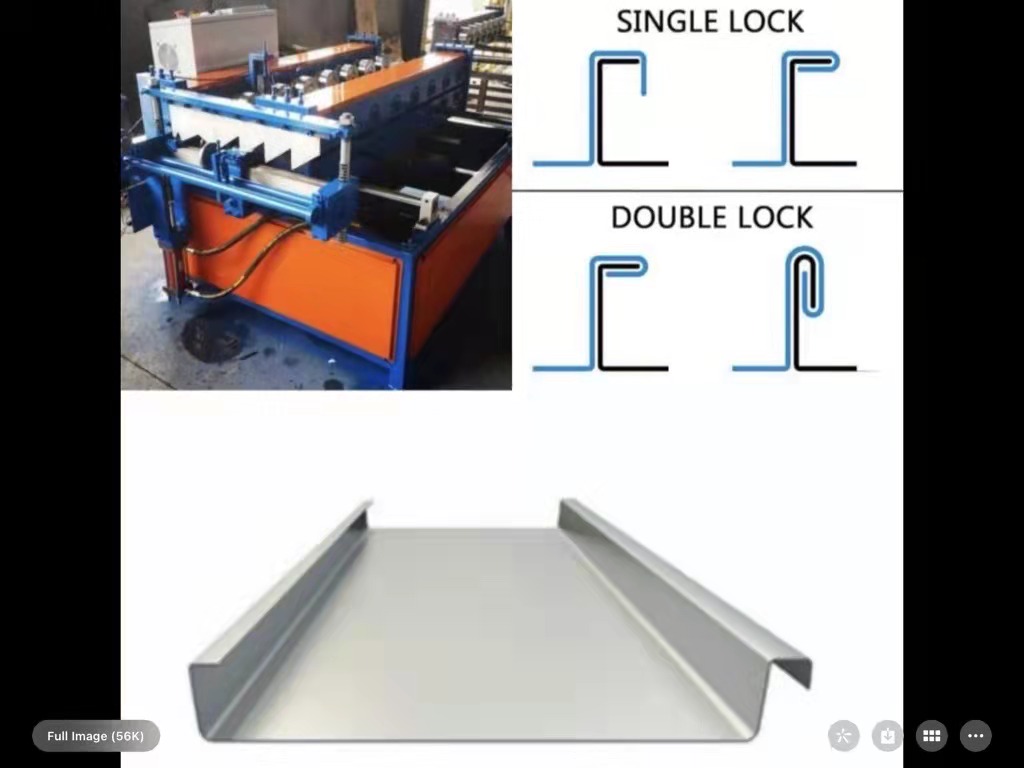

The Xinnuo self clip lock standing seam roof panel cold roll forming machine is specifically engineered to fabricate seamless roofing panels with an exceptional level of accuracy. By utilizing a continuous roll forming process, this machine eliminates the need for manual adjustments, resulting in reduced labor costs and increased productivity.

2. Advanced Features and Components:

This cutting-edge machine boasts several advanced features that set it apart from conventional roll forming equipment. Its precision roll forming system ensures consistent panel profiles, while the automatic stacking and cutting mechanism guarantee seamless integration with downstream processing. Additionally, the machine incorporates a user-friendly control panel, allowing operators to adjust parameters effortlessly for optimal performance.

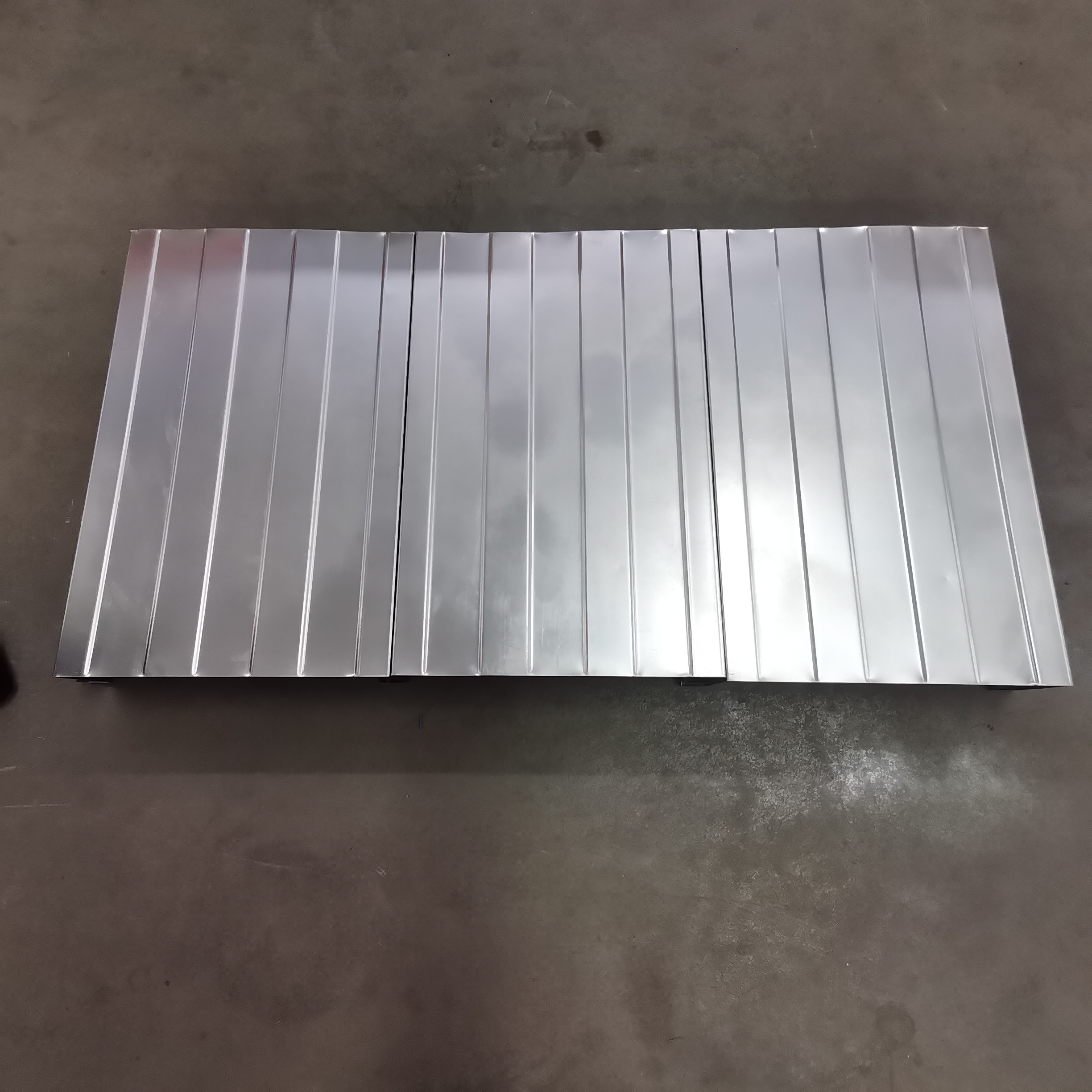

3. Quality and Durability:

The Xinnuo self clip lock standing seam roof panel cold roll forming machine is built with utmost precision and durability. It utilizes high-quality materials and components, ensuring excellent performance and longevity. The machine undergoes rigorous quality control measures throughout the manufacturing process to meet international standards, resulting in reliable and superior products.

4. Versatile Applications:

This state-of-the-art machine caters to a wide range of roofing applications. Its ability to produce custom-length standing seam roof panels allows for seamless installations on various architectural designs. Whether it be residential, commercial, or industrial projects, the Xinnuo self clip lock standing seam roof panel cold roll forming machine provides the flexibility to meet diverse customer requirements.

5. Streamlined Workflow and Cost Efficiency:

By automating the roll forming process, the Xinnuo self clip lock standing seam roof panel cold roll forming machine significantly enhances workflow efficiency. Its quick setup and minimal downtime ensure time-effective production runs. Additionally, reduced labor requirements and improved material utilization contribute to overall cost savings, making this machine well-suited for both small-scale and large-scale roofing projects.

6. Enhanced Roofing Performance and Longevity:

The standing seam roof panels manufactured by the Xinnuo self clip lock standing seam roof panel cold roll forming machine offer exceptional weather resistance, durability, and longevity. The precise panel profiles and secure clip lock system guarantee a watertight and structurally sound roofing solution. Additionally, the machine’s innovative design minimizes the risk of panel distortion and corrosion, ensuring superior performance for years to come.

Conclusion:

The Xinnuo self clip lock standing seam roof panel cold roll forming machine represents a significant advancement in the field of roofing construction. With its advanced features, versatile applications, streamlined workflow, and superior quality output, this state-of-the-art machinery elevates the standards of standing seam roof panel manufacturing. Whether it be for residential, commercial, or industrial applications, the Xinnuo self clip lock standing seam roof panel cold roll forming machine is your go-to solution to achieve efficient, precise, and durable roofing installations.

Post time: Nov-24-2023