In the realm of modern construction, the importance of efficient and precise machinery cannot be overstated. With its cutting-edge technology and exceptional craftsmanship, the Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine emerges as a game-changer in the industry. This comprehensive article delves into the intricacies of this machine, highlighting its features, benefits, and its crucial role in streamlining the construction process.

Enhancing Construction Efficiency:

The Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine is meticulously designed to optimize efficiency in floor decking panel production. Through its advanced automation system, this machine showcases unparalleled precision and consistency. Each meticulously formed metal sheet contributes to the production of high-quality floor decking panels, ensuring an end product that surpasses industry standards.

Precision Engineering:

At the core of the Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine lies precision engineering. This state-of-the-art equipment is engineered with utmost care to deliver impeccable results. Through the process of cold roll forming, the machine ensures exceptional dimensional accuracy and surface smoothness. This precision promotes efficient installation, reducing wasted time and material.

Advanced Features:

This machine boasts an impressive array of advanced features, making it a prime choice for modern construction projects. The incorporation of a PLC control system enables easy operation and guarantees consistent output. Additionally, the machine offers adjustable parameters, allowing customization to meet diverse project requirements. The use of high-quality materials ensures durability, extended machine lifespan, and minimal maintenance needs.

Seamless Floor Decking Panel Production:

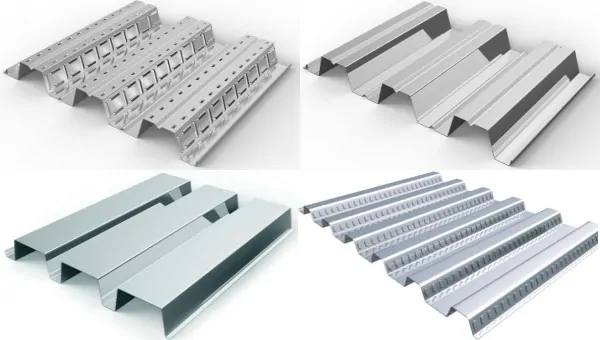

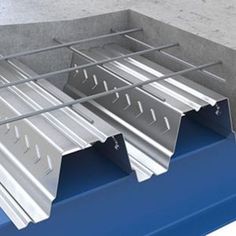

The Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine seamlessly manufactures floor decking panels of varying sizes and specifications. Its versatile design and adjustable parameters adapt to different construction needs, offering unmatched flexibility. This machine excels in accurately forming trapezoidal or wave profiled sheet metal, enabling swift assembly and installation on construction sites.

Optimized Construction Process:

Integrating the Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine into the construction process yields several benefits. First and foremost, it significantly reduces labor costs by automating the production of floor decking panels. Moreover, the machine’s high-speed performance ensures swift production, minimizing project duration and enhancing overall efficiency. The precision-formed panels fit perfectly, minimizing the need for modifications during installation.

Durability and Longevity:

The durability of the Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine ensures long-term usage without compromising functionality. With its robust construction, the machine can withstand heavy workloads, making it an ideal investment for ongoing construction projects. Its ability to produce consistent, high-quality floor decking panels also contributes to improved structural integrity and longevity of the final construction.

Conclusion:

In the fast-paced world of construction, the Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine stands as a reliable and efficient solution for floor decking panel production. Combining cutting-edge technology, precision engineering, and an array of advanced features, this machine streamlines the construction process while ensuring exceptional quality. Investing in this high-end machinery elevates construction efficiency, reduces costs, and guarantees perfect installation results. Embrace the Xinnuo-Steel Floor Decking Panel Cold Roll Forming Machine, and witness a new era of precision, speed, and excellence in construction projects.

Post time: Dec-12-2023