OEM/ODM Factory Panel Roll Forming Machine - c purlin roll forming machine – Xinnuo Detail:

*Detail

C purlin is widely applied in the purlin and wall beams of steel structures. It can be combined into lightweight roof truss, brackets, or other building components, as well as used for columns, beams, and arms in mechanical engineering.

Xinnuo has accumulated near 22 years’ experience in producing C purlin roll forming equipment. The C purlin roll former we made is distinguished for competitive price, high stability; and easy operation. It is designed with stepless shearing system, which allows the shearing for different dimensions of purlins to be done without the need of replacing cutter. The adjustment upon the bottom size is realized by increasing and reducing the spacers. About 3-4 hours are needed each time to change the purlin’s dimension.

*Features

1. The main feature of the C-purlin roll forming machine Is that its wheels and middle plate can be moved simply by adjusting the screw; and that operators can change the purlin’s dimension by regulating the screws on the side of the roll former.

2. Xinnuo has developed the fully automatic C purlin roll forming machine, which is controlled by computer to regulate the purlin’s dimension. The bottom size varies from 80mm to 300mm.

3. The c purlin roll former contributes both to save the time used for replacing cutters, and to cut on the labor cost.

4. For this roll former, all of the work involving size change is conducted automatically by computer. With the PLC control system, it will only take few minutes to change the purlin model and what operators have to do Is just to enter the instruction on the touch screen.

5. Shearing and punching devices are available to process the steel strips in advance so that they will not be wasted when replacing the purlin’s dimension.

6. For some cheap machine configuration, we recommend the C purlin roll former with flying saws, It comes at an affordable price and is competent in finishing the dimension change from 80mm to 300mm.

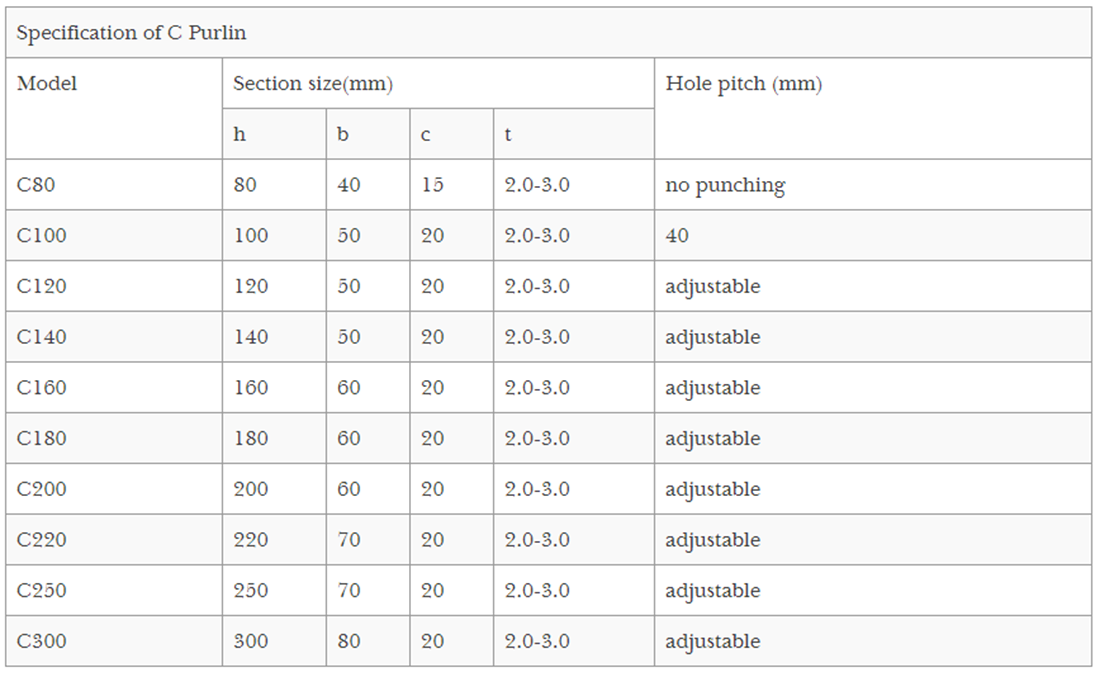

*Specification

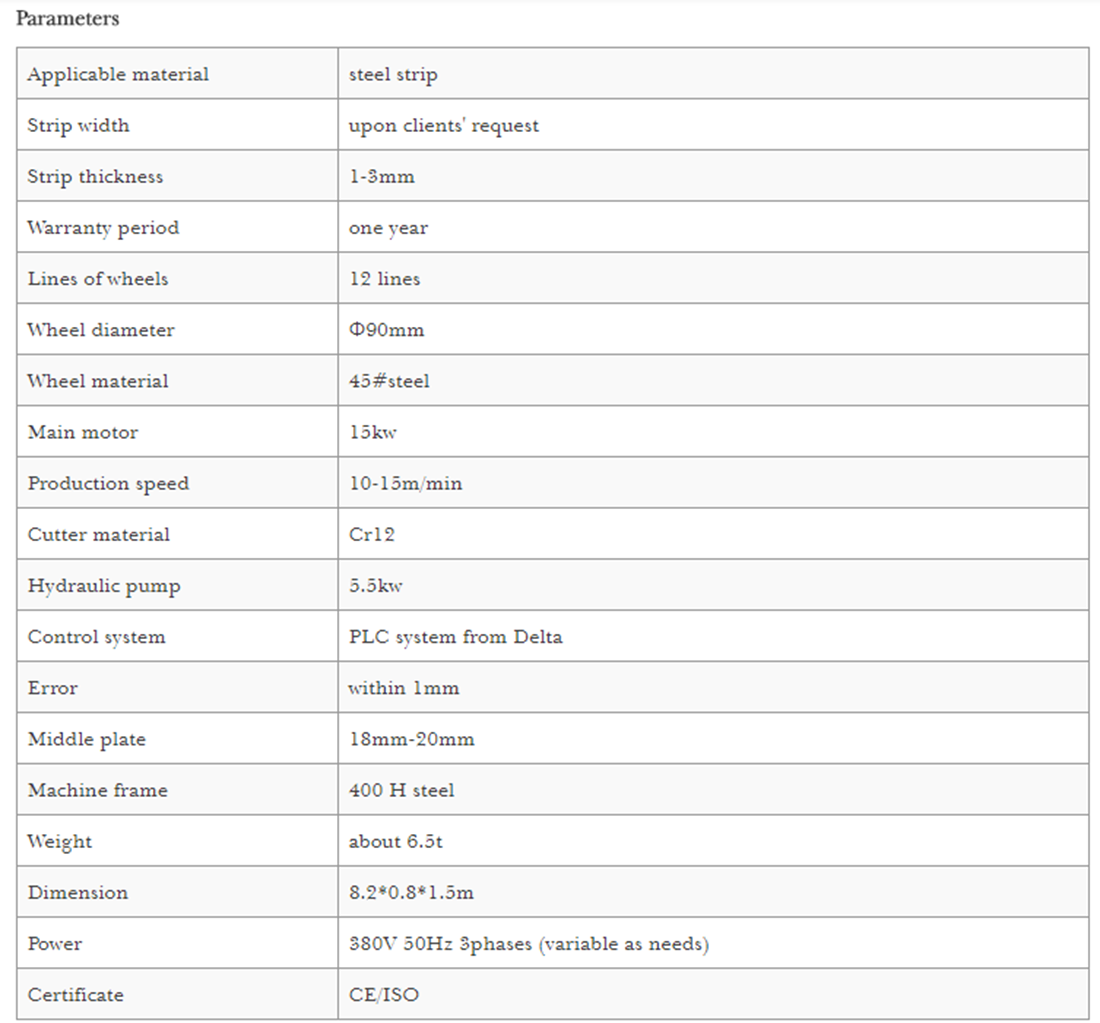

*Parameter

*Application

Product detail pictures:

Related Product Guide:

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for OEM/ODM Factory Panel Roll Forming Machine - c purlin roll forming machine – Xinnuo, The product will supply to all over the world, such as: Guatemala , Nigeria , Brasilia , We offer the great variety of products in this field. Besides, customized orders are also available. What's more, you will enjoy our excellent services. In one word, your satisfaction is guaranteed. Welcome to visit our company! For more information, please come to our website.If any further inquiries, please feel free to contact us.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

-

Reasonable price for Ridge Cap Forming Machine ...

-

Factory source Shutter Roll Forming Machine - ...

-

China Manufacturer for Steel Roll Forming Machi...

-

Factory selling Metal Door Making Machine - sh...

-

china Roll Forming Products Manufacturers - ri...

-

Chinese Professional Roll Forming Machine For S...