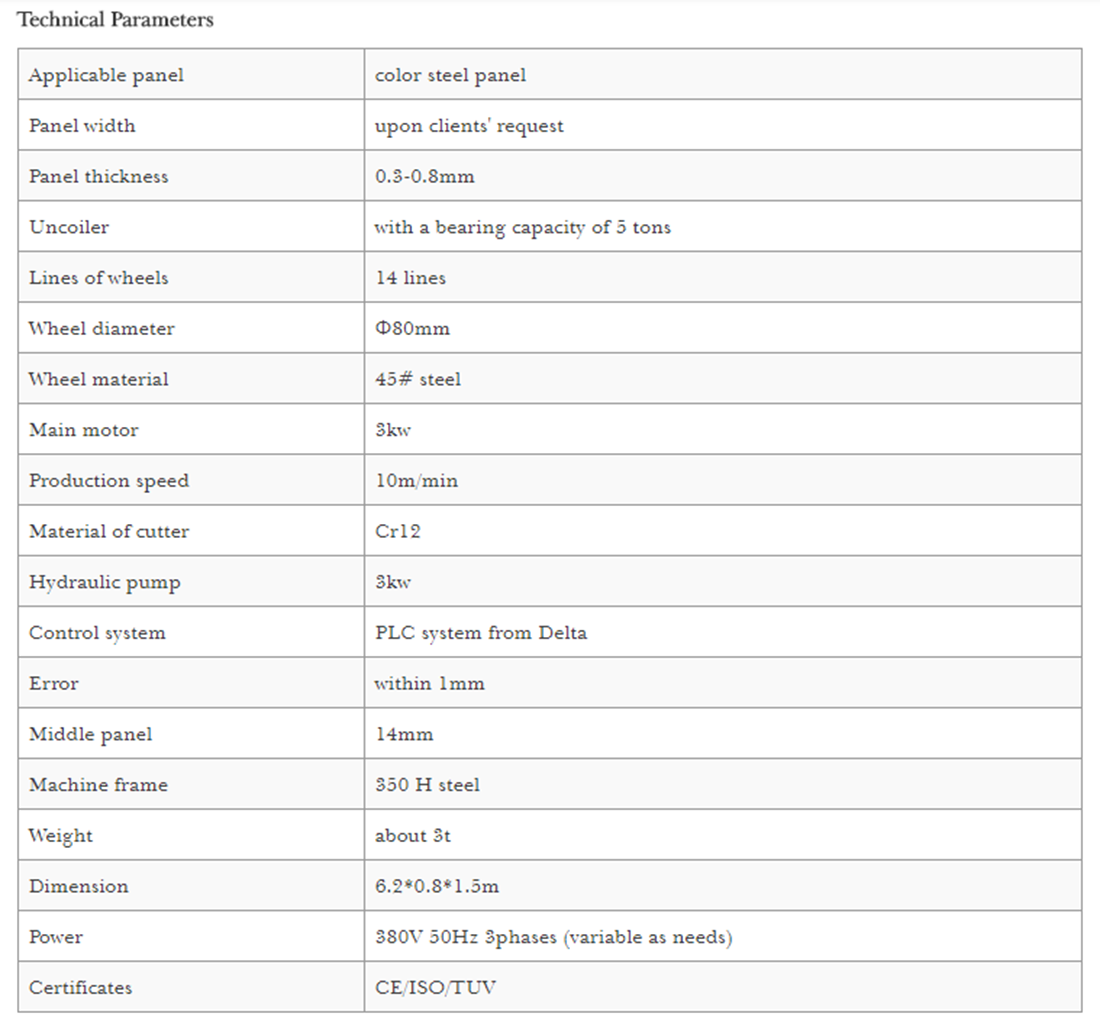

OEM/ODM Manufacturer C Purlin Roll Forming Machine - ridge cap roll forming machine – Xinnuo Detail:

*Detail

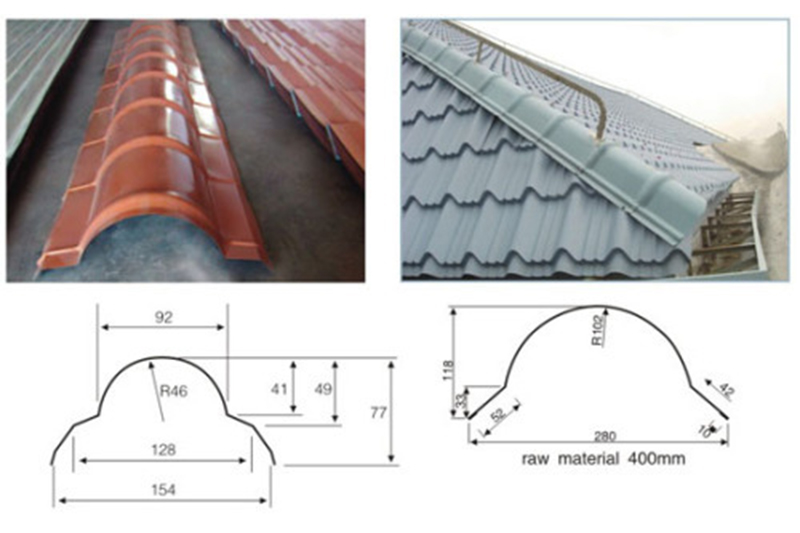

Ridge cap roll forming machine is used for making ridge cap, which is a kind of roof panel installed along the ridge line of a sloped roof. To enhance the panel roll former’s efficiency, we have adopted Cr12 molybdenum- vanadium steel for its cutting blades to realize high hardness and wear resistance.

Xinnuo has been devoted to fabricating cold roll forming equipment for near 22 years. The abundant experience allows us to know exactly what customers need. No matter what kinds of roof panel you are looking for, come to Xinnuo and we will customize the cold roll forming machine for producing panels with the required width and thickness you want. Besides, our equipment has been certified by CE, ISO, and TUV

*Application

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for OEM/ODM Manufacturer C Purlin Roll Forming Machine - ridge cap roll forming machine – Xinnuo, The product will supply to all over the world, such as: Brunei , Slovakia , Iran , We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

We have been looking for a professional and responsible supplier, and now we find it.

-

Hot-selling Roll Forming Machine Manufacturers ...

-

Roll Forming Machine Manufacturers factory - C...

-

Wholesale Roof Rolling Machine Manufacturers - ...

-

High-Quality Bottom Beam Of Shutter Door Roll F...

-

Forming Machine pricelist - double layer roll ...

-

oem C Purlin Roll Forming Machine pricelist - ...