-

door frame roll forming machine

door frame roll forming machine Product Description: Equipment components Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable. Main parameters 1.Echnical parameters Name fully automatic rate galvanized slat sliding door guid... -

solar photovoltaic support roll forming machine

solar photovoltaic support roll forming machine our solar support strut channel roll forming machine is belong full automatic complete production line this machine with 6 sizes of profiles, but we also could design the machine as your need. Our Services Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller’s factory while before delive... -

solar photovoltaic support roll forming machine

solar photovoltaic support roll forming machine Product Description: 1.Final product main parameters Feeding material width range: 40-300mm Feeding material thickness:1.5-2.5mm Suitable material: Q235, Q345 cold steel strips, hot galvanized strips Produce speed: 20m/min The min length of product: 2000mm The final product straightness error: ≤±1.5 mm /1500 mm The final product angle error: ≤±1.5 mm /1000 mm The final product... -

car panel roll forming machine

car panel roll forming machine Equipment components: Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable. Main parameters 1.Echnical parameters Suitable to process Color steel plate, galvanized sheet, aluminum coils and etc. Width of the f... -

corrugated panel roll forming machine

corrugated panel roll forming machine No. Main parameter of the machine for reference 1 Suitable to process Color steel plate 2 Width of the plate 850m 3 Thickness of the plate 0.3-0.8mm 4 De-coiler Manual one, can load 5 tons raw material 5 Rollers for forming 11rows 6 Diameter of the roller 70mm 7 Rolling material Carbon Steel 45# 8 Main motor power 4kw 9 Productivity 8-12m/min 10 Cutting method Hydraulic mould cutting 11 Material of the cutting blade Cr12m... -

ridge cap roll forming machine

ridge cap roll forming machine Technical parameters: 1 Name of commodity & specification Ridge tile roll forming machine 2 Main motor power 4kw, 3 phase 3 Hydraulic motor power 3kw 4 Hydraulic Pressure 10-12MPa 5 Voltage 380V /3phase/ 50 HZ (or as your requirement) 6 Control System PLC Delta Inverter 7 Main Frame 400mm H-Beam 8 Backboard Thickness 18mm 9 Chain Size 33mm 10 Feeding Material color steel coils 11 Feeding Thickness 0.3-0.8mm 12 Feed... -

double layer panel roll forming machine

double layer panel roll forming machine We design each machine according to user requirement. Below techinical parameters can be adjusted if needed. 1.control system: automatic PLC frequency control ,text screen. 2.roller steps:9/11 rows 3.main power:4kw 4.pump power:4kw 5.Diameter of roller: Φ72mm 6.max speed:12m/min 7.feeding width:1000mm 8.the effective width:850/840mm,tolerance ±1/100 9.thickness of the plate:0.35-0.6mm 10.the dimension of main roll former: 7600mm×1300mm×145... -

join-hidden panel roll forming machin

join-hidden panel roll forming machine 1 Suitable to process Color steel plate, galvanized sheet, aluminum coils and etc.2Width of the feeding material1000mm3Roller station22 rows4Thickness of feeding material0.3-0.8mm5Productivity8-12m/min6Rollers’ material45# steel7Diameter of shaft75mm8Voltage380V 50Hz 3phases9Wall thickness of main forming machine14mm steel plate10Main forming machine body300 mm H steel11Motor power7.5+4 kw12Size7500*1500*1400mm13WeightAbout 5.8 T ... -

automatic stacker

automatic stacker Product Description Our advantageous: 1: Factory direct supply price. 2: We have exported for more than 10 years. 3: Our customer are from about 34 countries. 4: We have the professional research team. We can make the machine according to your requirement. 5: High-end and high-grade design 6: Free technical support and Free accessoies supply. The Parameter of auto stacker: 1 Run-out motor power: 0.75KW 2 Max spe... -

cutting machine

cutting machine Product Parameters: 1. Suitable to process: color steel plate, steel plate, galvanized sheet and so an. 2. Raw material thickness: 0.2-1.0mm 3. Raw material width: 1350mm 4. Motor power: 3KW 5. Size: 1.9*1.9*1.5m 6. Weight: about 1.0Tons Our advantageous: 1: Factory direct supply price. 2: We have exported for more than 10 years. 3: Our customer are from about 34 countries. 4: We have the professional research team. We can... -

slitting machine

slitting machine Product Description Hydraulic shearing machine is widely used for shearing the steel plate, easy to operate, no wastage, high efficiency and low price. 1. Working Flow Of the line Decoil—leveling—slitting—cut to length—recoiler 2. The technical parameters for reference: NO. Name parameters 1 Powe of slkitting machine line 11kw 2 quantity of strips(Max) as you need 3 raw material thickness as customers’ requirement 4 widt... -

hudraulic decoiler

hudraulic decoiler Product Description: The function of decoiler is to support raw material for all kinds of roll forming machines. Main parameters: 1. Suitable to process: color steel coil, steel coil, galvanized coil and so an. 2. Raw material width: max 1250mm 3. Size: 1.7*1.7*1.5m 4. Weight: about 2.5Tons Our Services Guarantee: 12 Months guarantee. if some part of the machine is broken. we will supply the best part,but if the damaged parts due to operate error... -

shelf rack roll forming machine

shelf rack roll forming machine Equipment components: Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable. Main parameters No. Main parameter of storage rack roll forming machine 1 Suitable to process Color steel plate 2 Wid... -

downpipe roll forming machine

downpipe roll forming machine Main parameters of DOWNPIPE roll forming machine 1 Suitable to process PPGI, 550MPA 2 Roller station 23 rows 3 Thickness of feeding material 0.47mm 4 Productivity 8-12m/min 5 Rollers’ material GCr15(quenching and chroming) 6 Diameter of shaft 70mm(The modulation process) 7 Weight About 6T 8 Size 11000*1200*1000mm 9 Voltage 380V 50Hz 3phases 10 Wall thickness of main form... -

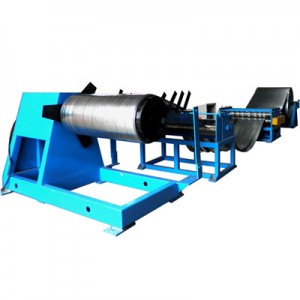

curving machine

We are manufacturers and designers of cold roll forming machines from China.

Products mainly include

Roof/Wall roll forming machine.

C/Z/U purlin roll forming machine.

EPS/Rock-wool sandwich panel roll forming machine production line.

Light steel frame machines and so on.

Based on 27 years of experience,We can supply you one-stop solution to fulfill all your needs in metal cold roll forming industry. -

Hydraulic arch crimping curving roofing machine arch roofing machine

Hydraulic arch crimping curving roofing machine arch roofing machine Product Description 1. the advantage of xinnuo brief curving roof forming machine it has reasinable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the costomer with limit area or site operation. 2. Main Parameter and specification of the xinnuo brief curving roof forming machine We design each machine according to user requirement. Below techinical paramete... -

sandwich panel production line

Sandwich panel production line is especially designed for producing insulation composite board. With stepless speed regulation system, It Is able to produce corrugated composite panel efficiently at one time. Sandwich panel roll forming machine has been an indispensable device in fabricating roof panels and wall panels in plants and warehouses, among other buildings. -

floor deck roll forming machine

The metal deck roll forming machine in Xinnuo is mainly available in some models: 688. 720, 750,915,1000,1025 and so on. 1000model is popular in many countries. In addition to the standard ones, Xinnuo provides custom roll formers to meet clients actual requirements. -

Stone Coated Steel Roof Panel Production Line

Xinnuo provides automatic sandblasting line, which is designed to smooth the surface of cold rolled plate. The sandblasting equipment we provide is generally used as a part of panel roll forming line. The panels after sandblasting treatment can be applied as UV-proof/thermal-insulated roof panels. -

rain gutter forming machine

Rain Gutter equipment is the production of building roof gutter roll forming machine, the production of gutter refers to the building roof between the two hip concave part, used for house drainage.

Roll forming equipment supplier

More Than 30+ Years Manufacturing Experience

- info@hbxinnuorollforming.com

- 0086-15632788505