Wholesale Gypsum Channel Roll Forming Machine Factory - Stone Coated Steel Roof Panel Production Line – Xinnuo Detail:

Stone Coated Steel Roof Panel Production Line

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building

manufacturing, and have features such as nice appearance and durable.

| NO. | Our advantageous: |

| 1 | Factory direct supply price. |

| 2 | We have exported for more than 10 years. |

| 3 | Our customer are from about 34 countries. |

| 4 | We have the professional research team. We can make the machine

according to your requirement. |

| 5 | High-end and high-grade design |

| 6 | Free technical support and Freeaccessoies supply. |

| NO. | Main parts of stone coated production line: |

| 1 | Slitting and cutting device |

| 2 | Lace shearing device |

| 3 | 315 four column press machine |

| 4 | Auto bottom gule spraying device |

| 5 | Auto stone coated device |

| 6 | The first time drying device |

| 7 | Auto face gule spraying device |

| 8 | The second time drying device |

| 9 | Forming machine |

All technical parameters can be changed, according to user’s need.

Guarantee:

12 Months guarantee. if some part of the machine is broken. we will supply the best part,but if the damaged parts due

to operate error,buyer will pay for the shipping fee.

After-sale service:

We sent technician to your country to fix the machine.the buyer shoule bear all the cost includng:visa,roundtrip ticket

and suitable accommodation,also buyer should pay the salary 100USD/DAY.

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming

machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway

guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines,

shutter slat door forming machines, downpipe machines, gutter machines, etc.

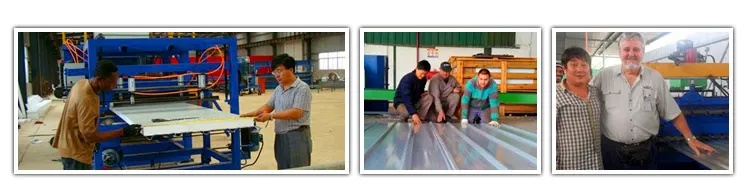

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Wholesale Gypsum Channel Roll Forming Machine Factory - Stone Coated Steel Roof Panel Production Line – Xinnuo, The product will supply to all over the world, such as: Macedonia , Provence , Mexico , Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

-

Top Quality Roof Forming Machine - c purlin ro...

-

China K Span Roll Forming Machine Pricelist - ...

-

High-Quality Metal Roof Panel Machine Manufactu...

-

OEM/ODM China Roll Forming Machine Price - Hyd...

-

Corrugated Sheet Rolling Machine - floor deck ...

-

factory low price C Purlin Forming Machine - c...