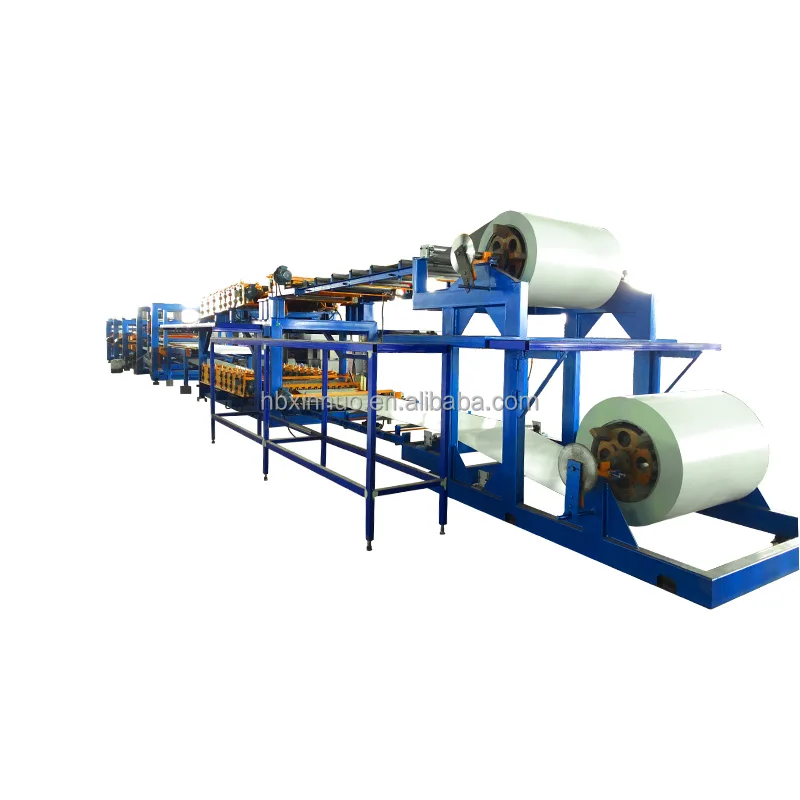

Wholesale Sandwich Panel Production Line Manufacturers - z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line – Xinnuo Detail:

Product Description

Specification

|

No.

|

main parameter of Sandwich panel forming machine line

|

||

|

1

|

Suitable to process

|

Color steel plate

|

|

|

2

|

Width of the plate

|

1000&1200mm

|

|

|

3

|

Rollers

|

17-44rows

|

|

|

4

|

Dimensions

|

38.0*2.25*2.5m

|

|

|

5

|

Power

|

30kw

|

|

|

6

|

Thickness of the plate

|

0.3-0.8mm

|

|

|

7

|

Productivity

|

2-6m/min

|

|

|

8

|

Diameter of the roller

|

Φ90mm

|

|

|

9

|

Weight

|

About 15 T

|

|

|

10

|

Voltage

|

380V 50Hz 3phases

|

|

|

11

|

Material of the cutting plate

|

Cr12

|

|

|

12

|

Processing precision

|

Within 1.00mm

|

|

|

13

|

Control system

|

PLC control

|

|

|

sandwich panel standards

|

|

|

Length

|

Min cut length: 3 m

Max stacker length: 15 m |

|

raw material standards

|

|

|

Coil thickness

|

0.4~0.6mm (the coil surface should be flat,

no arch and the others surface trouble.) |

|

Material coil yield strength

|

235MPa

|

|

Material coil max width

|

see detailed profile drawings.

|

|

Material coil max weight

|

5 T

|

|

Material coil inner diameter

|

Φ508,Φ610 mm

|

|

EPS core material

|

|

|

density

|

≥18Kg/m3

|

|

straight rate

|

≤1mm/m

|

|

arch degree

|

≤3mm/m

|

|

panel surface

|

shoule be flat

no flat degree is ≤1.5mm/m, |

|

sandwich panel length

|

longer than 5 meters

|

|

wool material

|

|

|

fiber length

|

≥100mm

|

|

cubage density

|

≥100Kg/m3

|

|

sandwich panel length

|

≥3 meters

|

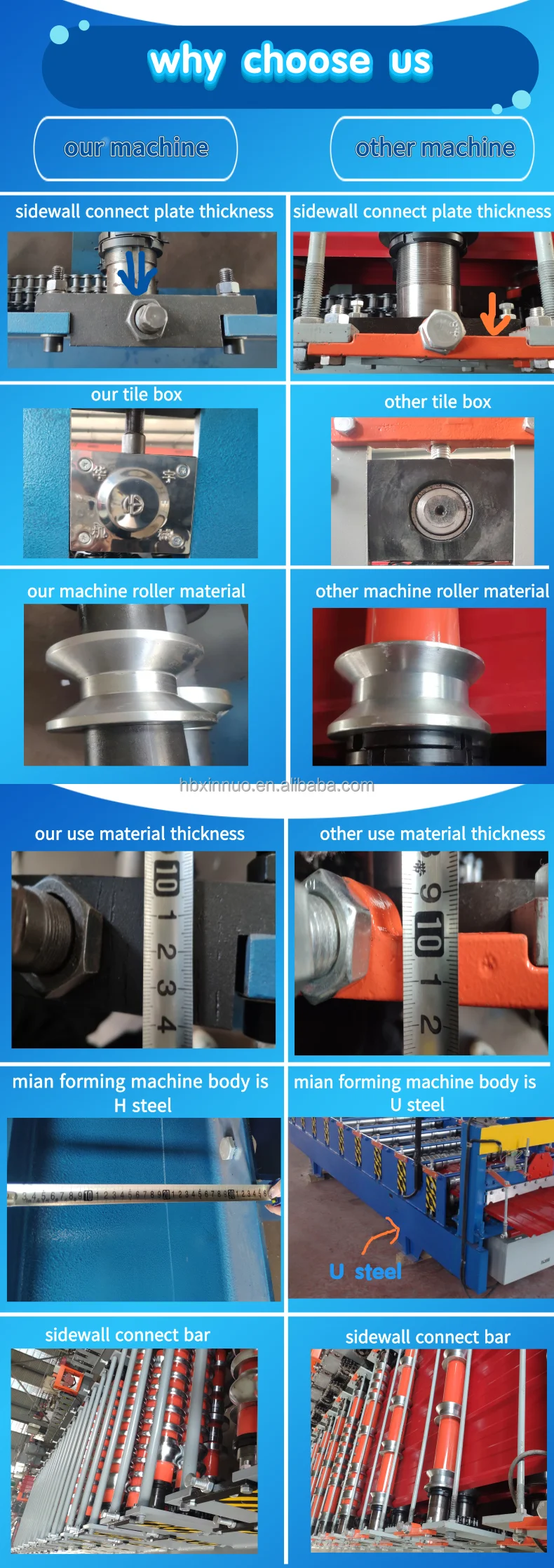

Why Choose Us

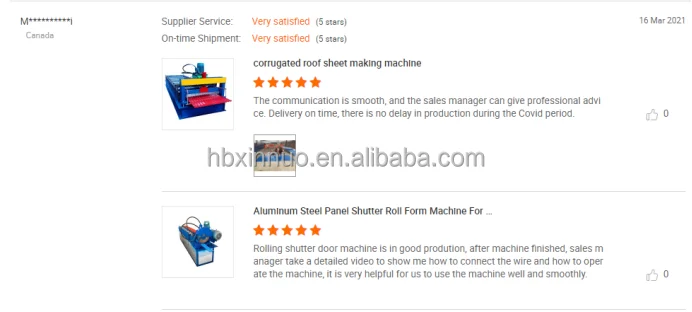

Customer Reviews

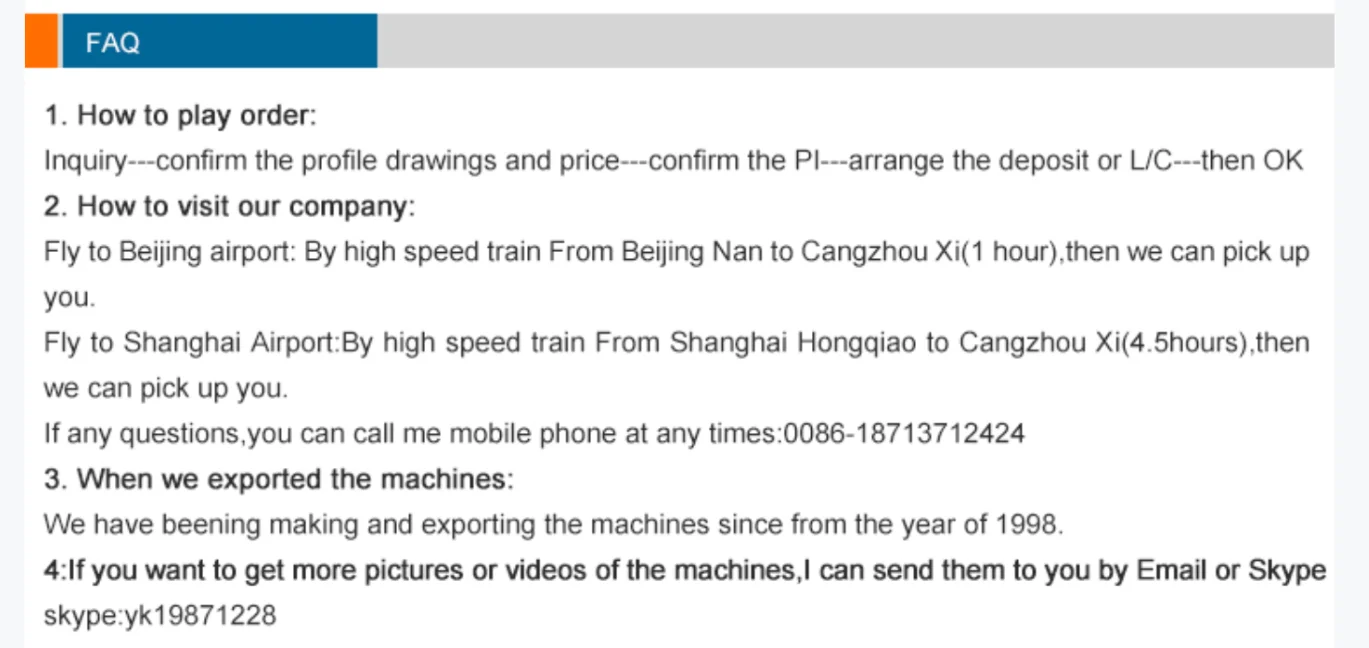

Packing & Delivery

|

Packaging Details:

|

Main machine is nude, the computer control box is packed with wooden frame.

|

|

Main machine is nude in the container, the computer control box is packed with wooden packaging.

|

|

|

Delivery Detail:

|

20 days

|

z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line

Our Advantages

LARGE CNC MILLING MACHINE

z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line a unique plant in Hebei Province.It directly mills the entire frame. The milling machine can make the machine’s large surface smoother and the machine is more perfect. z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line

SHOT BLASTING MACHINE

z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line can handle the entire machine frame or parts,making the rusty surface clean and smooth The surface of the product increases adhesion.z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line

NEW CNC MILLING

z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line make the backboard of purlin machine, also make the holes on backboard. This milling machine can milling the backboard more level, hole place is more precious. This can make the roller more level after installing,and then the purlin will be more straight.

Mechanical process

z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line, have high precious CNC grinders and milling machines,to make the rollers and shafts of the machine.After produce, have professional engineer to check if these are qualified.

From one roller to one machine, we do every step carefully to make sure the quality.

ELECTRICAL CONTROL

All the control system of our machines we

make by ourselves. we have a professional engineer to design and make the control system. z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line can make sure the after-sale service, when customer have problem with control, we can solve it timely.

ENVIRONMENT FRIENDLY SPRAYING EQUIPMENT

z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line electrostatic spraying equipment meets the environmental protection regulations of the Chinese government and guarantees the delivery time of the machine.

Company Profile

FAQ

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Wholesale Sandwich Panel Production Line Manufacturers - z-look automatic composite sandwich panel making machine aluminum sandwich panel manufacture line – Xinnuo, The product will supply to all over the world, such as: Sao Paulo , Romania , Brasilia , We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!