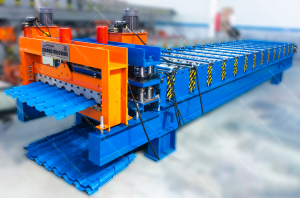

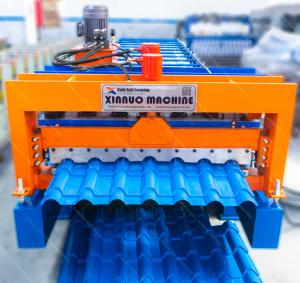

Introducing the Xinnuo-Long Span Metal Glazed Roof Sheet Cold Roll Forming Machine, a revolutionary solution for all your roofing needs. This incredible machine has been designed with utmost precision and expertise to provide you with the highest quality results and unmatched performance.

Crafted with state-of-the-art technology, the Xinnuo-Long Span Metal Glazed Roof Sheet Cold Roll Forming Machine offers unrivaled efficiency and productivity. It seamlessly blends functionality and innovation, enabling you to effortlessly create beautiful and durable metal glazed roof sheets.

Designed with the customer in mind, this machine offers a user-friendly experience. Its intuitive interface allows for easy operation, ensuring that both professionals and beginners can excel in roofing projects. With its high-end performance, you can save time, money, and effort while achieving outstanding results.

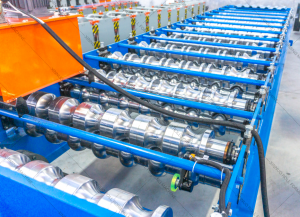

At the heart of this machine lies its cold roll forming technology. This cutting-edge feature ensures flawless precision and accuracy in every sheet produced. The metal glazed roof sheets created by this machine boast superior quality and incredible durability, making them ideal for both residential and commercial projects.

One of the key advantages of the Xinnuo-Long Span Metal Glazed Roof Sheet Cold Roll Forming Machine is its versatility. It accommodates a wide range of materials, including steel, aluminum, and galvanized sheets. This flexibility allows you to meet the unique requirements of any project, regardless of its complexity or size.

Furthermore, this machine offers exceptional speed and efficiency. It can produce metal glazed roof sheets at a remarkable rate, enabling you to complete projects quickly and meet tight deadlines. This efficiency translates into increased productivity and higher profits for your business.

Not only does the Xinnuo-Long Span Metal Glazed Roof Sheet Cold Roll Forming Machine excel in performance, but it also prioritizes safety. It has been engineered with robust protective features to ensure the well-being of operators. This includes safety devices such as emergency stop buttons and safety covers, guaranteeing a secure working environment.

Maintenance of this machine is hassle-free, thanks to its durable construction and high-quality components. With regular care and minimal effort, you can keep it running smoothly for years to come. Its long service life minimizes downtime and maximizes your return on investment.

In conclusion, the Xinnuo-Long Span Metal Glazed Roof Sheet Cold Roll Forming Machine is the ultimate solution for your roofing projects. With its unparalleled performance, efficiency, versatility, and safety features, it will exceed your expectations every time. Don’t miss the opportunity to take your roofing business to new heights with this remarkable machine. Invest in the Xinnuo-Long Span Metal Glazed Roof Sheet Cold Roll Forming Machine today and witness the transformation it brings to your work.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.